After the river sand is mined, it is inevitably doped with impurities such as soil and particles, and the river sand is of low quality. A sand washing plant is needed to achieve simple river sand cleaning, fine sand recovery, and wet sand dehydration. The overall structure of the LZZG water washing sand equipment is simple, it occupies a small area, it is also very convenient to install, and the operation is simple. The reliable design of the transmission part makes it effective to reduce the failure rate, and it can maintain a high operation even under harsh environmental conditions. effectiveness. The bucket sand washer has a simple structure, less wearing parts and small floor space, and the impeller drive bearing device is isolated from water and water-receiving materials, and the failure rate is low. The spiral sand washer has a strong cleaning capability and is often deployed in a large sand production line. Southeast Asia exports sand The countries that export sand in Southeast Asia are mainly Malaysia, Vietnam, Indonesia and Cambodia. Among them, the sand in Malaysia is…

More >

According to the "Cambodian Minerals Law", mining in Cambodia is divided into individual mining and industrial mining. Individual mining means that the local residents in the mining area carry out manual mining on their own land, and it must be less than 7 people. No mechanical equipment and explosives are allowed. The depth is not allowed to exceed 20 meters. The purpose is to help people improve their lives. The mining certificate is issued by the mineral bureau of the province where it is located and is valid for one year. Industrial mining is issued by the Ministry of Mines and Energy. It is divided into exploration licenses and mining licenses. Only companies with certain funds and technologies are eligible to obtain them. At present, most companies only have exploration licenses. Fees for small mining farms Individual mining requires buying land, or renting land, and then buying sand making and sand washing equipment. Generally, a small sand and gravel plant costs 80,000 to 200,000 US dollars. The establishment of a sand washing plant must require legal procedures. Recently, a team…

More >

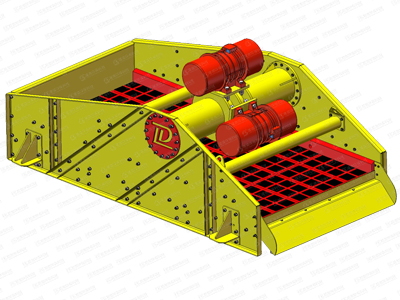

The screening and washing machine is used for washing, dewatering and grading of gravel aggregates, piling mud and silica sand. The machine has a compact structure, small footprint, can be quickly installed and moved, and can quickly start working. The combined screening equipment can be equipped with a crusher Sand making machine, used in sand factory and metal ore production. Advantages 1. One machine completes various operations such as cleaning, screening, recycling and dehydration. 2. The rear part of the screen surface adopts a plate structure to form a water reservoir, and an additional weir is added to extend the cleaning time and the material cleaning effect is better. 3. The overall screen surface lengthens, which is more conducive to screening. 4. Equipped with a fine sand recovery device to effectively recover the fine sand lost during the washing process. Structure 1. Sand washing and dewatering screen 2. Ordinary motor 3. Separation and recovery device 4. Support spring 5. Water tank under sieve 6. Rubber hose 7. Slag paddle pump 8. Slurry pump motor Working Principle The materials are evenly…

More >

The single-layer vibrating screen can screen two different grades of materials when screening materials. The assembly type and welding type of the high-frequency linear vibrating screen have certain differences in product installation and components. The assembly type uses a circular tube structure motor beam, which can effectively avoid welding stress. Name: High frequency linear vibrating screen [Structure Mode]: Assembled structure Feeding granularity: ≤10mm Processing capacity: 60-180t / h Applicable Industry: 1. Wet sand production line, sand washing, desilting and dewatering operations. 2. Coal slime recovery and other operations. 3. Dry discharge and dry pile operation of tailings in the dressing plant. 4. Other industries related to dehydration, sludge removal, and mediating. SINGLE LAYER VIBRATION SCREEN FEATURES 1. The main body adopts an assembled structure to reduce welding connections and effectively control cracks caused by welding stress. 2. The motor installation beam uses a round tube structure with even torque distribution. 3. The vibration source selects a 4-level vibration motor to achieve high-frequency vibration, which is more conducive to material dehydration and mud removal operations. 4. The amplitude can be adjusted…

More >

With the development of the economy, the world's demand for sand and gravel continues to increase. The river gravel washing plant designed by LZZG acts in different sand making environments. Cobblestone sand production line generally consists of vibrating feeder, crusher, sand making machine, belt conveyor, circular vibrating screen, sand washing machine, dewatering screen, and other equipment. Pebble crushing and washing plant Directly mined stone or produced sand contains more impurities, which is not conducive to sales. Therefore, many cobblestone sand production lines will be equipped with sand washing machine equipment. Under normal circumstances, the vibratory screening equipment already has some functions in the soil, without the need for sand washing equipment. However, if gravel aggregates with high cleanliness requirements are required, it is often necessary to equip the sand washing machine or bucket wheel to type sand. Sand Washing Machine. working process Jaw Crusher —- Coarse Crushing Cone crusher (impact crusher) —- secondary crushing Sand making machine —- Fine crushed sand making Vibrating screen —- screening Sand washing machine —- cleaning Dewatering screen —- drying Vibration feeder-finished product Requirements…

More >

Global sand and gravel washing machine demand is growing. It is estimated that the global sand and gravel output is about 50 billion tons. Based on the total population of 7.7 billion in the world, the per capita sand and gravel consumption is about 6.5 tons. In terms of regions, Asia accounts for 66% of global sand and gravel production. An aggregate washing plant Looking ahead to 2030, the global sand and gravel industry trend is still positive. Population growth (8.5 billion people in 2030), economic development, and global urbanization (expected to reach 60% in 2030), the three major factors jointly promote the growth of the sand and gravel industry. Global sand and gravel production is expected to reach 60 billion tons in 2030. [caption id="attachment_4656" align="alignnone" width="400"] Aggregate washing machines[/caption] Colombia sand aggregate production Colombia currently has a total output of about 147 million tons of sand and gravel, with a per capita consumption of about 3 tons. The main challenge facing the country's sand and gravel industry is that half of the country's sand and gravel is illegally…

More >

This set of sand washing plant is manufactured for a sand making plant in Peru. The output capacity is 100 tons per hour, and the sand washing plant is used for ore sand washing. Low cost, less equipment wear, durability, low water consumption, low noise during operation, and meet national environmental protection production requirements. On the other hand, the structure of the sand washer is relatively simple. The impeller transmission bearing device of the equipment is isolated from the water-receiving material, which prevents the bearing from being damaged due to water immersion and pollutants. Therefore, it can be applied to various working environments and has a good Layout design, good sealing. Machinery shipped this time: round vibrating screen, wheel sand washer, spiral sand washer, dewatering screen, fine sand recycling machine, etc. This set of sand production plant: [Production capacity] 50-200t / h [Finished product size] 0-5mm [Composition equipment]: Vibrating feeder, jaw crusher, sand making machine, vibrating screen, sand washing machine, belt conveyor, etc. Sand-making production line process The materials from the sand making machine are returned to the vibrating screen…

More >

Cage drum screen is another new generation of screening equipment after plane vibrating screen and cantilever vibrating screen. It is widely used for screening various solid fuels with a particle size below 400mm. Cage drum screen has many advantages such as wide adaptability of coal type, simple coal feeding mode, high screening efficiency, large screen component, low energy consumption, low noise, strong sealing performance, long service life, small maintenance, and convenient maintenance. Its screening capacity is 150t / h - 420t / h, or even higher. How the device works The main structure of the cage drum screen is a screening cylinder, which is a screen composed of a plurality of annular flat steels. The whole is inclined with the ground plane, and the outside is sealed by a sealing spacer to prevent environmental pollution. Through the variable speed deceleration system, the screening cylinder is rotated at a certain rotation speed, and the coal is separated from the top to the bottom through the screening cylinder, and the fine material is discharged from the lower part of the front end…

More >

The mechanical mud desander mainly has a vibrating screen. The mud passes through the vibrating screen to destroy the structure of the mud, so that the cuttings and sand slide down from the sieve, and the mud flows out from the sieve. The sandstone vibrating screen uses the vibration exciter as the vibration source, and the high-efficiency soft link device is applied. When the equipment works to generate vibration, the equipment is protected. The unique structure screen will not be blocked, and the tilt of the screen surface of the equipment can be Adjusted by a unique adjustment device, the service life is greatly improved, resulting in high practical value. Sand and gravel sieve can sift many materials, such as ore, aluminum powder, copper powder, sand, ore, alloy powder, sand, stone, abrasive powder, refractory material, limestone, quartz sand, and other materials. The hydraulic mud desiler has a mud cyclone desander, which first pumps the mud into a funnel container by a sand pump. The pumping direction is directed along the tangential line to the inner wall of the container.…

More >

Although lignite is low in mining cost, it is usually only used on site because of its high water content and low energy density, which is not suitable for transportation or trade. In addition, with the slowdown in China's consumption growth, coupled with the vigorous development of US shale oil, the international coal market price is lower, which also makes the situation of relatively high-cost hard coal power plants relatively prosperous. Vibrating screen can be used in Lignite quality improvement lignite coal vibrating screen c has high moisture and ash content, low calorific value, easy weathering in the air, and is not conducive to long-distance transportation. When used directly as a fuel, the combustion efficiency is low, and the greenhouse gas emissions are high and the pollution is serious, which has been greatly limited for a long time. The upgrading of lignite refers to the reduction of moisture in lignite by thermophysical or thermochemical methods, and the increase of the calorific value of the product, which is convenient for transportation, high heat utilization efficiency and low pollution. In Germany, coal-fired…

More >