Construction waste recycling sand making equipment 300TPH

June.06,2020

June.06,2020

The South Ring Road project is a key urban construction project that Luoyang City is accelerating. At the same time, the project also has a feature, the amount of demolition along the route is very large, and a large amount of construction waste transportation will bring about waste of resources and dust pollution.

“After research and experiments, we decided to try to process construction waste along the route into roadbed cushions on-site, instead of traditional gravel and cobblestone,” the project investor said.

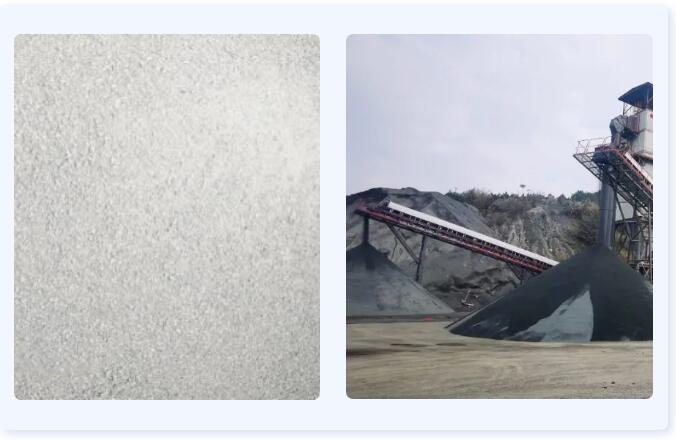

Construction waste crushing sand making equipment

The construction of sand by construction waste is mainly achieved by the mobile equipment of the mobile crusher. After the excavator digs out large pieces of construction waste and puts it into this machine, this machine will spray fine powder particles, and the other end of the conveyor belt is a large diameter block of particles, the initial end of the conveyor belt There is also a magnet-like horizontal conveyor belt, which directly sieves out steel and other metals in construction waste, and the rest is called recycled mixture, which can be directly used for road base construction. In order to suppress dust pollution, there is a sprinkler next to the crusher to carry out dust reduction operations.

Advantages of recycling construction waste

Construction waste is processed by mobile crusher and sand washing machine, which can complete the processes of crushing, sieving, light material processing, dust suppression, etc. in an instant, and produce different types of finished aggregates-gravel and sand, according to different uses. Adjust the coefficient of the crusher to produce particles of different sizes.

Equipment of different powers can process 70 tons to 300 tons of construction waste per hour, and can also achieve dust suppression at the source during the process to prevent harm to the surrounding residents. After treatment, the utilization rate of construction waste is as high as 90%, half of which can be used as the roadbed cushion of municipal roads, and the other half can be made into bricks to achieve the resource utilization of construction waste.