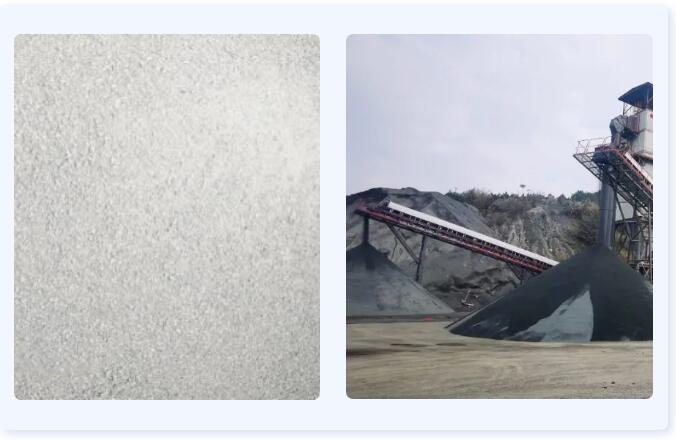

Process and equipment for making sand with tailings

June.04,2020

June.04,2020

Tailings are “waste” discharged by mining companies under certain technical and economic conditions, but at the same time they are potential secondary resources. When technical and economic conditions permit, they can be effectively developed again.

What equipment is needed to make sand from tailings

The waste rock chips from different sources have different lithologies, different mining and crushing processes, and have very different physical properties. At present, there is insufficient systematic research on the performance of rock chips, and the law of the quality of rock chips and their impact on concrete performance is mastered. insufficient.

The low-quality stone chips have large powder content, rough surface, sharp edges and corners, difficult mud removal and shaping technology, and large investment; the problem of mud removal and shaping is not solved, and it is not conducive to the convenience of concrete, increasing the amount of cement, poor market acceptance .

For different types of waste rock chips, targeted sand making process is required, and the performance of the manufactured sand is also different. Therefore, there are higher management and monitoring requirements for the production of sand and the use of machined sand. Enterprises at this stage I still don’t understand this, and I just want to apply it in a simple way. As a result, the expected economic and environmental benefits are not realized, and the enterprise loses its motivation and determination to practice.

Tailings crushing sand making process

First, the waste rock chips are sieved, and the particles larger than 5mm (accurately speaking, the upper part of the sieve with a sieve hole length of 4.75mm square hole sieve) are crushed by a vertical shaft impact crusher, which also has a shaping effect and breaks. After the machine is air-separated (air screening), particles larger than 0.075mm are used as part of the machine-made sand.

The waste rock chips are sieved, and the particles smaller than 5mm are subjected to air separation. Among them, the particles larger than 0.075mm are judged by their particle shape. If the particle shape is good, it is directly used as a part of the machine sand; if the particle size is not good, Still need to go through the vertical shaft impact crusher for reshaping and then air separation, particles larger than 0.075mm are used as part of the machine-made sand.

According to the requirements of the sand powder for the crushed stone chips and the particles smaller than 0.075mm after the crusher crushing, according to the requirements of the powder content of the machine sand, part of it can be used as the stone powder in the machine sand, and part of it can be sold as stone powder products.

The quarry waste rock chips have a large output and low utilization value. Based on the full understanding of the physical properties of waste rock chips of different rock types and crushing processes, the quarry waste rock chips are processed and processed by using appropriate production techniques. Machine-made sand, instead of river sand, is used to prepare concrete and mortar, which can not only solve the problem of shortage of construction sand and environmental pollution of waste rock chips, but also improve the utilization rate of resources.