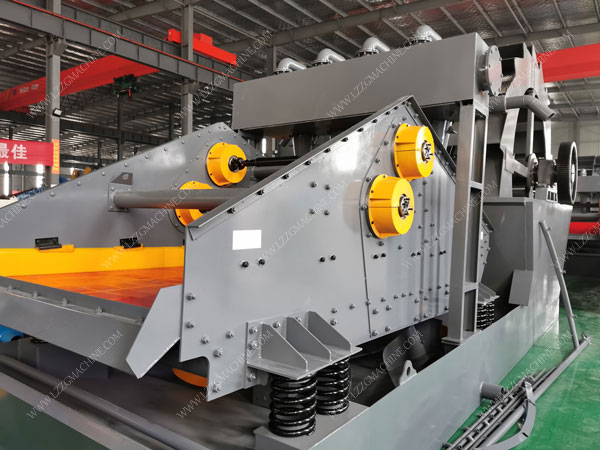

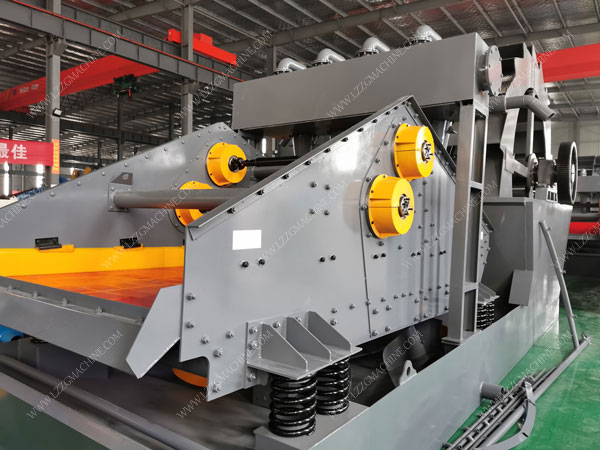

The silica sand dewatering screen adopts dual-motor self-synchronization technology, universal eccentric block and adjustable amplitude vibrator. It is mainly composed of screen box, vibration exciter, supporting system and motor. Two unconnected vibrators operate synchronously and reversely. The centrifugal force produced by the two sets of eccentric masses is superimposed along the vibration direction, and the reverse centrifugal offset is counteracted to form a single excited vibration along the vibration direction, making the screen box reciprocating. Straight line movement.

Performance advantages of dewatering screen

1. The dewatering screen is made of ultra-high polymer polyurethane (UHMW-PE), which is resistant to impact, low temperature, abrasion, chemical corrosion, self-lubrication, and impact energy absorption. The impact resistance is among all plastics. Higher value, wear resistance is better than PTFE, nylon, carbon steel and other materials.

2. The vibration motor of the dewatering screen is easy to replace, and the base rubber spring is used to absorb vibration, so that the amplitude is not large, and the slow vibration can be taken off cleanly.

3. The dewatering screen can be customized according to the output and water content. The side panels of the fuselage have reinforced plates, the bottom is equipped with supports, the bottom is struck with horizontal bars, and the discharge port is supported by triangular steel plates. The plate is thick.

4. The vibration motor is fixed with high-strength bolts, and the bottom spring is a rubber spring. The quality of the spring will affect the life of the vibration motor. The fixed density of the sieve plate is high, and the sieve plate is reinforced with ribs.

5. After welding, the welder will strictly not have welding holes, and the bottom is supported by channel steel.

6. In addition, the sieve hole can be adjusted as required, the equipment has low noise and good dehydration effect.

7. Before delivery, the staff will debug it to check whether the vibration motor is normal and whether the exciter is operating well to ensure that the quality of the products delivered is guaranteed for customers.

The dewatering screen can also be used alone when it is used on some materials with low mud content, without a sand washing machine, such as quartz sand. Because quartz sand generally has low mud content, the use of sand washing machine to wash sand not only consumes energy but also has poor effect. More importantly, the investment cost of dewatering screen is lower than that of sand washing machine.