Screen mesh is a very important part for grading screen and dewatering screen. To obtain high quality products, the materials are must screening or dewatering by high quality screen. However, there are many different specifications of screens. Due to the complex shape of material particles, so usually there are several different representation methods such as screening particle size, sedimentation particle size, equivalent volume particle size, and equivalent surface area particle size. It is necessary to determine the size of screen mesh according to granular material.

Although the screens produced by different manufacturers look almost same, you will find that the structure is not same if you look closely. so you should pay more attention to the performance of screen, service life, final products and screening structure when you buy the screen. Only in this can we choose a good screen.Following is the purchase instructions about how to choose proper screen mesh for dewatering screen.

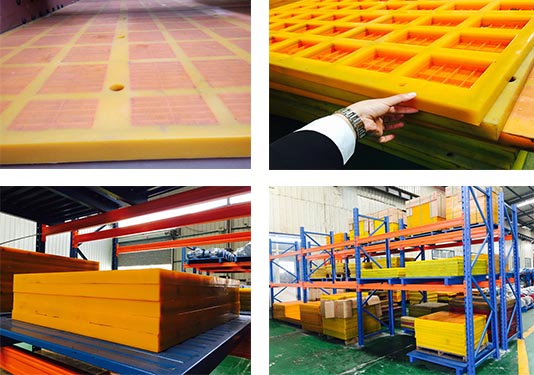

1. good screen is measured with computer-optimized optical instrument. The screen holes are

2. The mesh ribbon is hard, tough, and has a balance of tension

3. The frame of screen is shown in a precise shape. The bars and frame are in a sealed state. There is no crack, no distortion, and no break

4. The appearance of screen is generous and practical, and notaffect the sense of reality

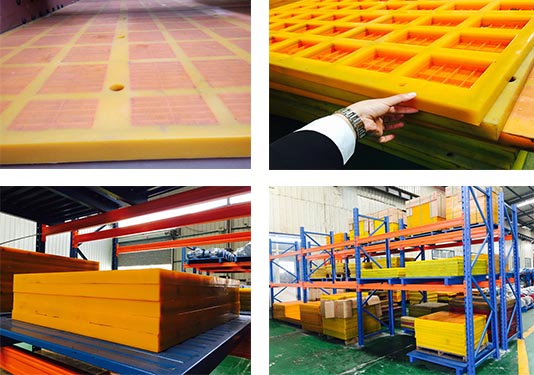

Therefore, polyurethane screen is a good choice if you want to purchase a good dewatering screen. All screening equipment and dewatering screens are used polyurethane screen of LZZG . This screen not only has good wear resistance, but also has long service life and good screening effect.