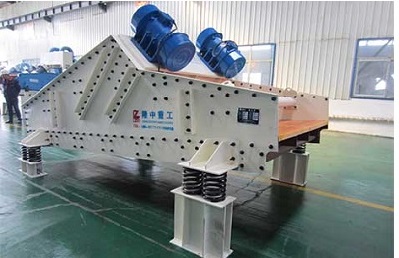

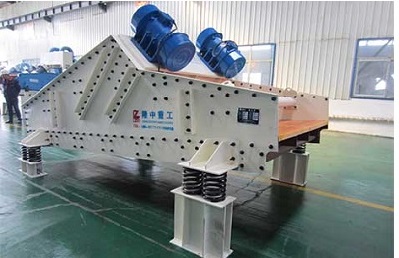

Dewatering screens are widely used in mineral processing, sand washing, coal preparation plants and other industries. There are more and more customers purchase dewatering screen. For these customers, they hope that the service life of dewatering screens will become longer, which will bring more economic benefits to themselves. So how to extend the service life of dewatering screens?

1. Bearings. Bearing is an important part of dewatering screen components. But it is inevitable to wet bearing during the dehydration process, then the bearing will rusted or corroded for a long time. So it is very important for the maintenance of bearings, can clean the bearing firstly, then apply a layer of anti-rust oil or anti-rust grease to the bearing.

2. The quality of parts. The quality of each component is also important to the service life of dewatering screen. It determines the quality of whole equipment, so must be sure to choose good quality parts. Our bearings are all from the same long-term cooperation company, the quality is guaranteed. The bearings used by our company have undergone various tests and can withstand the corrosion of strong acid. If the parts are damaged, we have after-sales repairs.

3. Vibration motor. When the dewatering screen is working, due to the large amplitude, some water will splash on the vibration motor, so the vibration motor is also very important. The selection of vibration motor directly affects dehydration effect. Our company uses a new type of vibration motor, which perfectly solved this problem.