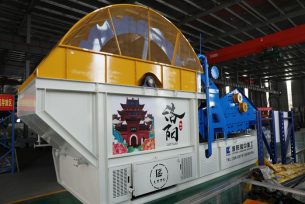

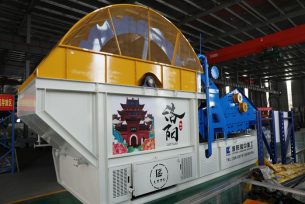

LZ150 Sand Washing Workstation

The sand washing workstation is an upgraded version of the traditional wheel sand washing & recycling machine. On the original basis, it not only improves the quality of accessories, but…

published date: 06-13-2019

How much to invest in building a sand and grave factory. To answer this question, we need to determine the following factors. The type and size of the sandstone plant determines its investment amount.

How much is the processing capacity? The investment in stone factories of different production scales varies greatly.

What is the processing material? Different hardness materials require different equipment.

How about engineering geological conditions? Infrastructure investment in soft foundations and hard foundations varies widely.

With the changes in the environmental protection policy for mining, the requirements for the opening of stone factories are also undergoing new changes. The traditional production, high pollution level, and small scale stone factory are gradually being replaced by environmentally friendly stone factories, which means The project also has more capital investment.

Pre-budget

1 License

The stone building factory must first obtain the mining license, business license, mining license, and safety production license. The handling of these documents requires a certain fee.

2 Mine site

The capital investment in the mining and leasing production sites is purchased, and the owner or department of the mine is consulted according to the local market conditions.

Medium budget

[blasting equipment] rock drills, drilling rigs, wind guns, etc.;

[transportation tools] forklifts, trucks, excavators, loaders, dump trucks, etc.;

The production of stone materials is inseparable from basic equipment such as feeders, crushers, vibrating screens and belt conveyors. If you want the finished sand, you need a sand making machine and a sand washing machine.

[Electrical system] motor, starter cabinet, cable, transformer, air compressor, etc.

The civil works and steel structures of the stone factory’s workshops, silos, crushers, vibrating screens and belt conveyors also require a corresponding budget. Usually the price is about 10% of the equipment cost.

Environmental protection is the general direction of the stone factory. After many governments have clearly requested environmental protection, they can only be put into operation. Specific environmental protection measures include installation of dust removal equipment, closed production workshops, hardened plant roads, and greening surrounding environments at major dust spots.

Third, the post budget

1. Logistics cost

The machine used for stone production belongs to large-scale mining equipment. If a foreign manufacturer is selected, the customer should consider the long-distance logistics cost of the equipment. Sorting of freight rates: air transport > land transport > water transport.

2. Labor costs

According to the needs of production and management, employees with professional skills, such as accounting, equipment operators, drivers, monitoring room duty personnel, etc., need to be employed. These are the software inputs of the stone factory.

According to experience, the size of the stone factory varies from tens of thousands to tens of millions. The above introduction can be found that the medium-term budget accounts for a large proportion of the price of the stone factory. Therefore, customers should invest more energy in selecting equipment, try to conduct on-the-spot investigations, and fully understand the qualifications, scale and after-sales service of many manufacturers. Then make a reasonable decision.

LZZG is a sand processing equipment manufacturer, the sand washer, sand recycling machines, sludge treatment and dewatering screen are exported to Europe, Australia, North America, South America, Southeast Asia, the Middle East, Central Asia, Africa and other countries.

The sand washing workstation is an upgraded version of the traditional wheel sand washing & recycling machine. On the original basis, it not only improves the quality of accessories, but…

In the clay and sand mining industry, the discharge coefficient of sand and gravel production: 2.0 tons/ton of sand washing wastewater, and the production scale is 150 tons of sand/d.…

LZZG can reasonably configure a complete set of sand and gravel washing equipment for customers, including rock crushing and sand washing equipment, sewage sedimentation equipment. The sand washing plant has…

The sand washing machine is used to clean the dirt, stones and other impurities contained in river sand, rock sand, weathered sand, etc. The washed sand is commonly called "water…