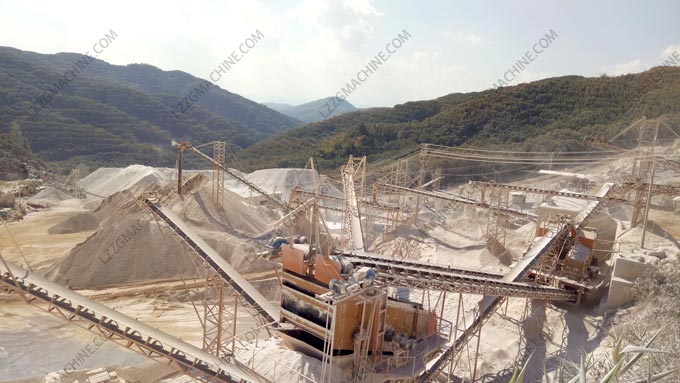

High-capacity stone powder vibrating screen

Stone powder vibrating screen is mainly used for screening stone powder after mining and crushing in quarries, and is sometimes used for ore dressing and coal dressing. Classification of materials…

published date: 06-18-2019

The circular vibrating screen adopts the cylindrical eccentric shaft exciter and the partial block to adjust the amplitude, the material sieve line length and the screening specifications are many, the structure is reliable, the excitation force is strong, the screening efficiency is high, the vibration noise is small, the sturdy and durable, the maintenance Convenient, safe to use, etc., the vibrating screen is widely used in product classification of mining, building materials, transportation, energy, chemical, and other industries. Long Ding circular vibrating screen can be used for screening coal, limestone, gravel, gravel, metal or non-metallic ore and other materials.

Chemical industry: resins, coatings, industrial drugs, cosmetics, paints, Chinese medicine powder, etc.

Food industry: powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce, juice, etc.

Metal, metallurgical mining: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electromagnetic material, abrasive powder, refractory material, kaolin, lime, alumina, heavy carbonic acid Calcium, quartz sand, etc.

Pollution treatment: waste oil, wastewater, dyeing, and finishing wastewater, additives, activated carbon, etc.

Features

1. Large processing capacity and high screening efficiency.

2. The vibrator is lubricated with bearing thin oil and external block eccentric structure. It has the characteristics of large excitation force, small bearing load, low temperature and low noise. (The bearing temperature rise is less than 35°).

3. The whole disassembly and assembly of the vibrator are convenient for maintenance and replacement, which greatly shortens the maintenance period. (It takes only 1 to 2 hours to change the vibrator).

4. The side plate of the sieve machine adopts the whole plate cold work, no welding, high strength, and long service life. The connection between the beam and the side plate is made of torsion-resistant high-strength bolts, and there is no welding and the beam is easy to replace.

5. The sieve machine adopts rubber spring to reduce vibration and has the advantages of small noise, long service life, stable over-common vibration zone and small dynamic load of each branch of the sieve machine.

6. The motor and the vibration exciter are connected by a flexible coupling, which has the advantages of long service life and small impact on the motor.

Stone powder vibrating screen is mainly used for screening stone powder after mining and crushing in quarries, and is sometimes used for ore dressing and coal dressing. Classification of materials…

The excitation force, vibration frequency and screening effect of the dewatering screen are closely related. Too small excitation force will cause poor screening effect, and excessive excitation force may cause…

The circular vibrating screen for mines plays a role in sand grading in the sand making plant. It has the characteristics of low noise, high efficiency, small size, and fast…

Vibrating screen is an auxiliary equipment in the production of mines, coal mines, electric power, steel and other industries. It can also be used in chemical, food, building materials, and…