In the petroleum field, fracturing refers to a method that uses hydraulic action to crack the oil and gas layer during oil or gas production. It is also called hydraulic fracturing.

Hydraulic fracturing technology refers to pumping fracturing fluid into an oil well under high pressure, resulting in high pressure at the bottom of the well. When the pressure is sufficient to fracturing the rock formation, the formation will generate fractures and expand forward to a certain space. In order to keep the fracture open, it is necessary to fill the fracture with proppant after the fracture. After the proppant is delivered, the viscosity of the fracturing fluid is reduced and allowed to flow back, so that a crack with high conductivity is generated.

Petroleum fracturing proppants currently used at home and abroad are generally divided into three categories: quartz sand, ceramsite proppants and film-coated proppants.

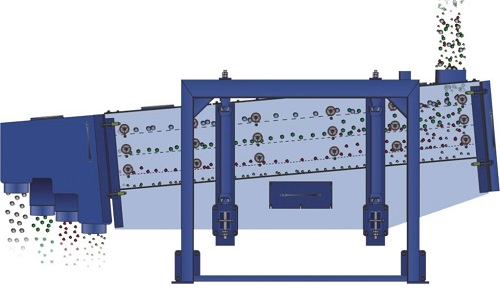

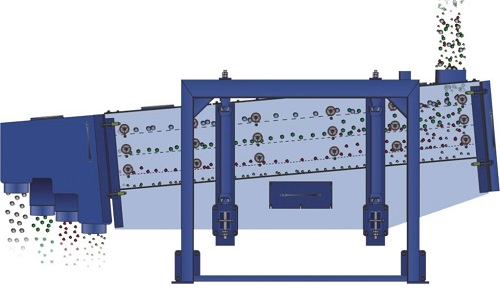

The oil fracturing sand production line is a set of special quartz sand equipment developed by our company for the production of oil fracturing sand. It has the advantages of large output, high efficiency, stable operation and round product size.

The technological process of the production line is: raw ore-pre-selection screening-scrubbing-desilting-magnetic separation-blocked sedimentation-dehydration screen-dryer-screening a series of processes to produce oil fracturing sand.

The oil fracturing sand production line developed for spherical sand for oil fracturing sand has the advantages of large output, high efficiency, stable operation and round product size.

Application

Spherical sand for oil fracturing sand.

Reliable quality of round shape

The production line has a round sand grain size and a higher compression value

Pertinent

For oil fracturing sand research and development production line, equipment can be configured according to customer conditions

Large output and high efficiency