300tph Basalt making sand production line

Basalt (sand) is the best material among the stones used for repairing roads, railways and airport runways. It has strong compressive resistance, low crushing value, strong corrosion resistance, and asphalt…

published date: 02-24-2020

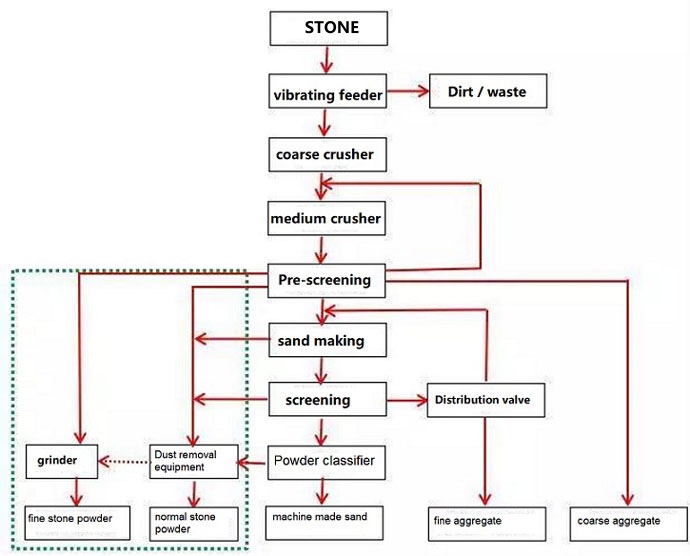

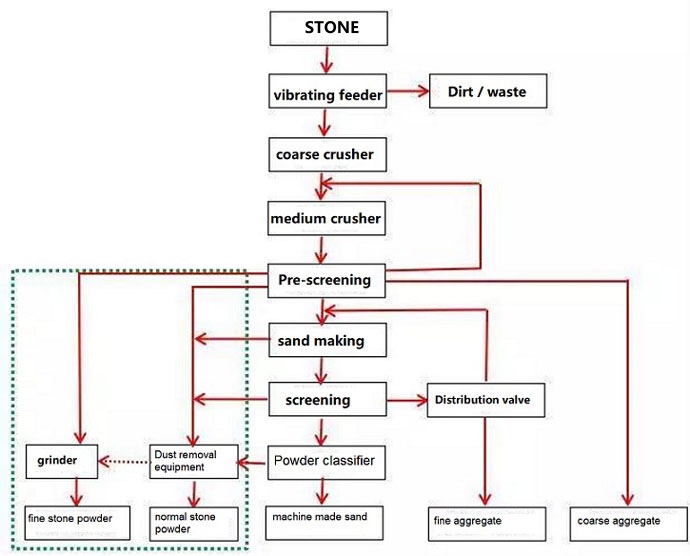

The large-scale environmental protection sand-making plant mainly crushes large-scale stones into sand that meets the requirements of particle size for later application in various fields. The specific configuration depends on the user’s operating conditions. There are technical teams here based on the operating environment. , Infrastructure construction, investment budget, and other tailor-made designs, here are provided two sets of plans for everyone, the specific large-scale stone plant sand, and aggregate production line configuration list is as follows;

1. Fixed large-scale sand production equipment configuration, the price is about $60,000 to $120,000

Feeder + Jaw Crusher (Coarse Crusher) + Impact Crusher (Medium Crusher) + Sand Making Machine + Vibrating Screen + Sand Washer + Conveyor;

① The specific length and position of the conveyor can be determined according to the actual site conditions

② According to the characteristics of the material, the size of the feed granularity, the output, etc., whether to use the secondary crushing equipment can be selected, and in order to meet the different processing needs of customers, cone crushers and dust removal devices can be configured. It is durable and can handle harder stones, such as river pebble, granite …

2. Large mobile sand production equipment, the price is about $60,000-$200,000

Large mobile sand making machine + sand washing machine;

If the granularity of raw materials is large, mobile jaw crusher can be equipped, with multiple units connected and high output.

Large-scale mobile sand production equipment can be directly driven to the job site, flexible transfer, no need for piling, integrated unit, small footprint, 1-2 people can control the entire site, saving raw material transportation costs.

1. Select sand equipment with green environmental protection certification mechanism, adopt fully sealed labyrinth structure dust removal technology, strong overall sealing type, good dust removal effect, and automatic dust removal function.

2. Equipped with high-standard dust collector, muffler, off-site spray facilities, etc., you can also choose to establish a sealed operation workshop and closed conveyor belt. If sand washing is used, a sedimentation tank can be set up to treat wastewater and recycle water use.

Basalt (sand) is the best material among the stones used for repairing roads, railways and airport runways. It has strong compressive resistance, low crushing value, strong corrosion resistance, and asphalt…

Recently, Yanhe Tujia Autonomous County, Tongren City, Guizhou Province, held a 2021 major project intensive commencement ceremony. Yanhe County's annual output of 5 million tons of new environmentally friendly fine…

The raw materials for machine-made sand are widely available. Granite, pebbles, river pebbles, tailings sand, construction waste can be used to produce sand by the sand making plant. The finished…

Delivery machinery: circular vibrating screen, spiral sand washing machine, dewatering screen, fine sand recycling machine, etc. This set of production line: [Production capacity] 50-200t / h [Finished product size] 0-5mm…