Heavy duty rock trommel screen working principle

The ore drum screen is generally composed of a drum, a frame, a funnel, a reducer and an electric motor. In addition, different placement schemes can be designed for the…

published date: 03-21-2019

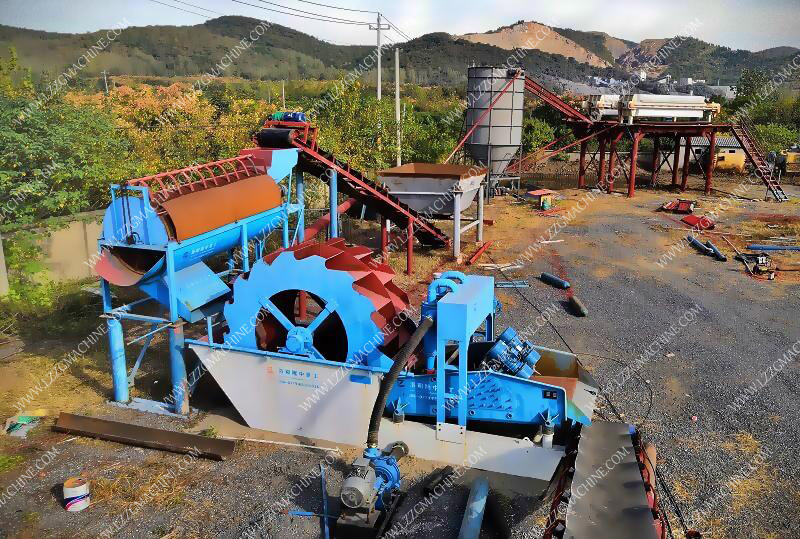

The sand gravel separator is the core equipment of concrete recycling system. It is mainly used to cleanse and recycle the sewage from the tanker and the sand in the residual concrete. The machine adopts foreign advanced concrete recycling technology, combines the characteristics of drum separation and spiral screen separation, and has made a lot of improvements on the wearing parts. It has simple operation, intelligent control, and the whole process is unattended and convenient. Fast, really fulfills the ultimate goal of your command, saves you a lot of manpower, material resources, financial resources, and easy maintenance, low power consumption, and makes it a hybrid station with its super high return on investment. Choosing our products is tantamount to choosing a huge fortune!

Trommel screen for sand and gravel separation

patented features (built-in sieve cage with a mechanical anti-blocking device)

The ore drum screen is generally composed of a drum, a frame, a funnel, a reducer and an electric motor. In addition, different placement schemes can be designed for the…

lzzg The special trommel screen for aggregate screening can meet the needs of screening stones of different diameters. The stone drum screen is composed of five parts: a hexagonal drum,…

The pebble roller screening machine is used to separate materials smaller than the specified size. The screen plate adopts a butterfly structure and is equipped with a uniformly distributed rotating…

Effect of concrete hardening performance Randomly adding water will destroy the water-binder ratio of the concrete mix, directly causing the concrete strength to decrease and affecting its durability. If the…