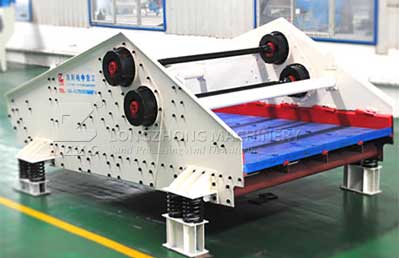

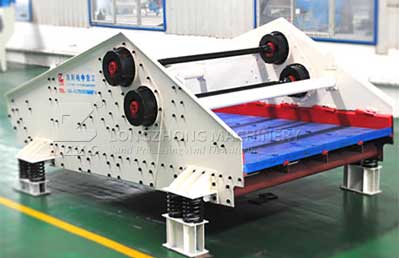

LZ series tailings dry discharge screen is a kind of vibrating screen specially used for dry tailing of metal tailings specially developed on the basis of high frequency sifting and combining metal tailings. It is mainly used for iron ore, copper ore, gold ore and aluminum. Dewatering of tailings such as mines. It is a new type of high-efficiency tailings recovery equipment designed for many problems in China’s large number of tailings dry sieves. It has a simple structure, low cost, high efficiency, low energy consumption, low noise and easy maintenance. Features.

Tags: tailings dry discharge, tailings dewatering screen, tailings recovery, high frequency tailings screen, tailings dry row dewatering screen, dewatering screen

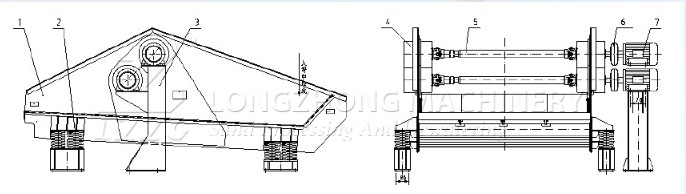

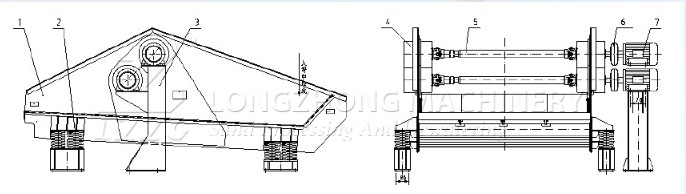

1, vibrator

The vibrator is mainly composed of a bearing seat, a rolling bearing, a main eccentric block, a main eccentric block, a shaft, an oiling device and a protective cover. Adjusting the angle between the main and the main eccentric block can change the magnitude of the exciting force.

The bearing adopts large clearance short cylindrical roller bearing (bearing for vibration equipment). The bearing and the bearing seat and the shaft are matched with special cooperation. The bearing temperature is generally below 50 degrees, the bearing life is doubled, and the vibrator is greatly reduced. Maintain workload and improve working environment.

The eccentric vibrator has been formed into a series of 8 specifications. It can be used on a circular vibrating screen or on a linear vibrating screen using self-synchronizing technology. It is currently the best used and longest life vibrator in China.

2, sieve box

The screen box is composed of a screen frame, a screen surface and a screen surface fixing device.

(1) Screen frame

The screen frame is an integral space metal structure. It is mainly composed of a side plate, an upper beam and a lower beam group, a support device seat, a side plate inner and outer reinforcing plate, and a longitudinal beam angle steel. The longitudinal beam angle steel is mounted on the lower beam for supporting the screen surface and the material, the support device seat is connected with the supporting device for supporting the weight of the vibration part of the whole sieve, the vibrator is directly installed at the two holes of the side plate, and the vibrator attachment is added inside and outside. Reinforcing plate. The main components and the side plates are all connected by torsion-cut high-strength bolts.

(2) Screen surface: The screen surface adopts polyurethane elastic plate type screen surface, the sieve hole is determined according to user needs, and the outer shape of the screen surface is common.

(3) Screen surface fixing device

The screen surface fixing method adopts the method of fixing the middle rail seat type screen surface at both ends, and the fixing method is used for importing the vibrating screen, and is suitable for the screen surface of the polyurethane edging, because the polyurethane has certain elasticity, through extrusion, the plate The raised portion of the screen face is embedded in the recessed portion of the rail seat. The rail seat is coupled to the upper longitudinal beam of the lower beam by bolts. The method is reliable and easy to disassemble.

3, tape coupling

The vibrator and the motor are connected by a tape coupling to isolate the motor from vibration. The coupling consists of two coupling halves and a tape that is joined to the tape by a pressure plate and bolts.

4, the support device

The screen is coupled to the foundation by four sets of support means. The support device is mainly composed of a top seat, a coil spring and a base.

5, universal joint shaft

The power is transmitted between the two vibrators through the automobile universal joint shaft, and the axial direction of the universal joint shaft is freely movable, thereby preventing the bearing from being subjected to the axial force.

6, motor and motor frame

The screen adopts two ordinary Y series motors, which are connected with the motor frame through bolts, and the motor frame is welded.

GP Tailings Dewatering Screen

Characteristics of tailings dry row dewatering screen

1. High working frequency, high vibration intensity, low moisture content on the sieve, high unit processing capacity, and high solid recovery when used for tailings dewatering.

2. Adopting the principle of self-synchronization, the motor drives the vibrator through the tire coupling, which has simple structure and low working noise.

3. Install at a negative inclination angle, and install the sieve surface of the dewatering section at a level of 45 degrees to increase the dewatering area and promote the dehydration of the material as soon as possible to form a filter layer.

4. In order to adapt to the differences in the properties of different tailings, the amplitude of the screen can be adjusted. The method is to adjust the angle between the main and auxiliary eccentric blocks to meet the dewatering effect of tailings with different properties, and try to achieve the best process effect.

5. The side plate and the beam are connected by torsion-shear type high-strength bolts, and there is no weld seam, which avoids the problem of side plate cracking caused by welding stress.

6. The vibrator is a block eccentric unit structure, which is easy to disassemble and maintain.

7. The bearing adopts special bearing for vibration equipment to avoid premature damage of bearing heat.

8. The mesh surface adopts polyurethane elastic screen surface, high opening ratio and elasticity, which is beneficial to dehydration.

9. The side plate of the screen surface is made of polyurethane material, the service life is long, the screen surface is fixed and reliable, and the side plate of the screen frame can be effectively protected from material scouring.