In the mineral processing industry, sand washing machines have an indispensable importance. When choosing a sand washing machine, the basic understanding of sand washing machine is the basis of our investment. Let’s take a closer look at the basic common sense of the sand washing machine.

1. Sand washing machine classification

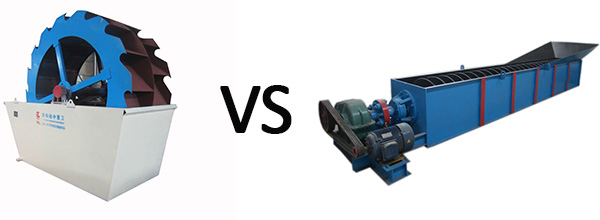

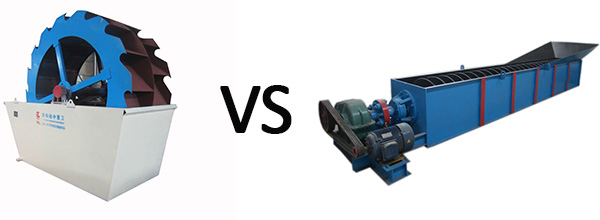

Sand washing machine is divided into wheel-type sand washing machine and spiral sand washing machine according to the structure, installation method and working principle.

(1) In terms of floor space, the wheel-type sand washing machine has a small footprint, mainly uses three-dimensional space, and is easy to move; the spiral sand washing machine is narrow and long, and covers a large area, mainly utilizing a plane space;

(2) From the production, the capacity of same model of bucket sand washing machine is slightly lower than that of spiral sand washing machine.

(3) From the price, the price of same capacity of sand washing machine is slightly lower than spiral sand washing machine.

2. Sand washing machine workflow

Materials enter to sand washing machine through the feeding equipment, the dust and impurities in sand is removed by the action of water flow flushing. In the process of washing sand, the wheel-type sand washing machine relies on the screening effect of screen, and the screw sand washing machine relies on the propulsion force of impeller.

The wheel type sand washing machine has three functions of cleaning, dehydrating and grading; under the driving of the impeller, the sand and stone are mutually ground to remove impurities covering the surface of the sand stone, and the cleaning and impurity removing function is completed. Therefore, the washing machine has high washing degree, the sand washing machine has less investment, and the power consumption is small, which can effectively save the production cost. The structure is novel and the cleaning effect is good: the novel sealing structure, the fully enclosed oil bath type transmission device and the adjustable overflow weir plate ensure the high efficiency and durability of the series products, the cleaning and dehydration effects are good, and the fine grain products remain stable.

The spiral sand washing machine achieves the purpose of cleaning by means of blade agitation. Compared with the traditional wheel washing machine, since the sand to be washed runs in the machine box for a long time and achieves full friction cleaning, the cleaning effect is ideal. It is suitable for the washing operation of fine-grained and coarse-grained materials. It is especially suitable for sand for construction and gravel for road construction. The spiral sand washing machine has low power consumption and high washing degree. The sealing structure is good, the fully enclosed transmission device and the adjustable jaw plate ensure the product is efficient, durable and has good cleaning and dewatering effects.