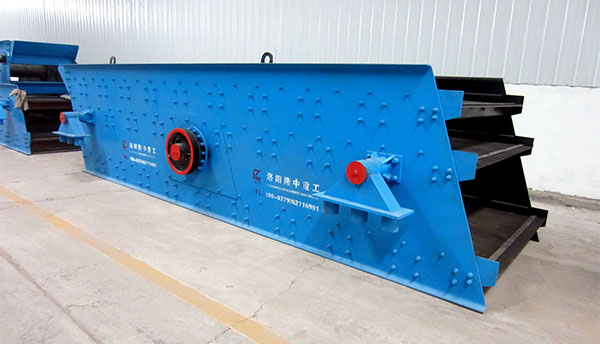

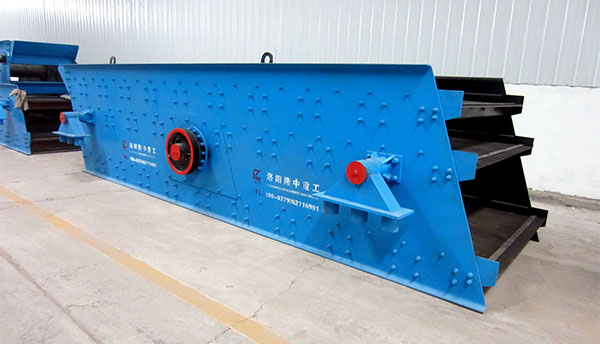

Circular vibrating screen is an auxiliary sand making equipment with large processing capacity and high efficiency. The circular screen can be customized according to the model or parameters provided by customers.

Structure

The screen box has a horizontal inclination of 15°~20°, screen mesh and vibration exciter are fixed thereon. The screen deck can be single layer, double layers and multiple layers; bearing seat of vibration exciter is fixed to the side wall of screen box; the two ends of main shaft of exciter are respectively equipped with pulleys and discs with eccentric weight; the center of main shaft also has an eccentric weight protruding toward the square, the combined force of two parts is eccentric and generates the exciting force of vibration.

Main parts

Circular vibrating screen is composed of a spring support group, a transmission device, a screen box, a support base, a thin oil lubrication vibrator, etc.; the drive machine adopts a petal coupling and a flexible disc coupling which are simple in structure, easy to manufacture and maintain; the vibrator adopts an eccentric structure and has a simple structure; transmission part adds an intermediate transition bearing seat, and the application of intermediate transition bearing seat effectively protects the motor and prolongs the service life of motor; The left side of screen frame can also be installed on the right side of screen frame; circular vibrating screen is seated, and the adjustment of screen angle can be achieved by changing the height of spring support.

Characteristics

1. Large processing capacity and high screening efficiency;

2. Large excitation force, small bearing load, low temperature and low noise;

3. The whole disassembly and assembly of vibrator is convenient for maintenance and replacement, which greatly shortens the maintenance period;

4. The side plate of sieve machine adopts the whole plate cold work, no welding, high strength and long service life;

5. The motor and exciter are connected by a flexible coupling, which has the advantages of long service life and small impact on the motor.