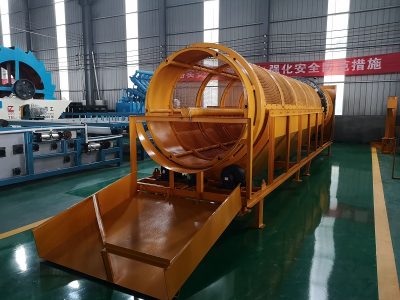

Simple to operate and inexpensive gold washing drum screen

Drum screen is a commonly used screening equipment in the gold washing process. It is suitable for screening various solid materials with a particle size of less than 300mm. It…

published date: 10-16-2019

With the development of the economy of various countries, the consumption of walnuts has risen rapidly. Although the planting area and annual output of walnuts have increased year by year, they still cannot meet the needs of the market. The price of walnuts continues to rise, and more and more fruit farmers have also joined the walnuts. Large-scale planting industry comes. Therefore, our company has developed a modern small-sized walnut peeling roller screen, which has been continuously improved after being put into the market for several years, and the products have been maturely pushed to the domestic market.

The new walnut screening and peeling machine is reasonable in price, the equipment is sturdy and durable, saves water and electricity, can use 220V lighting power for power supply. Machine processing walnut, greatly improve the quality of walnut, improve the mature rot of green walnut in the past, artificial peeling. Resulting in the blackening of the surface of the walnut reduces the pollution of the walnut kernel by the green walnut sweat, which causes the walnut kernel to become yellow, which is welcomed by the walnut processing enterprises. Walnut peeling machine removes the walnut, easy to preserve.

working principle

The drum type walnut peeling machine adopts the principle of centrifugal force of the drum screening machine. The green skin walnut enters the rotating cage from the right side through the fully automatic lifting conveyor. The rotating cage rotates at a high speed, and the outer layer of the walnut skin is continuously rubbed with the stainless steel rotating cage, forcing it. The surface of the green skin is broken and separated from the walnut under strong centrifugal force, so as to achieve the effect of peeling green skin.

Features:

1. Adopt advanced design concept

2. Easy to operate

3. Weighing accuracy

4. Excellent quality

5. Reduce costs

7. The device has a small space

10. Simple maintenance

Technical parameters of the cage type walnut peeling machine:

Processing walnut rate (ton / h) 4-5 tons (green walnut)

Production (ton / h) 2-4 tons (walnut)

Pass rate (%) 98%

Power (kW) 4kw

Voltage (V) 380V-220V

Drum size (mm) 1200 × 800 × 1300

About the manufacturer

The energy-saving and environment-friendly trommel/drum screen produced by LZZG can meet the different production requirements of customers. The finished aggregate meets the national high-quality building materials standards and can be widely used in large-scale construction. Peanut drum screen is suitable for crushing medium hardness materials such as limestone, slag, coke, coal and other materials in cement, chemical, electric power, metallurgical and other industrial sectors. If you want to know more about the operation of the peanut roller screen, please feel free to send inquiries.

Drum screen is a commonly used screening equipment in the gold washing process. It is suitable for screening various solid materials with a particle size of less than 300mm. It…

Gold placer contains more mud than primary ore, and mud easily wraps the ore sand to form cemented blocks and mud bodies. If it is directly fed into the separation…

The trommel screen has many advantages such as simple structure, large workload, durability, low cost and convenient maintenance. The power connector of the octagonal drum screening machine for large coal…

At present, the screening tools are mainly divided into fixed screen, rotary screen, vibrating screen and swing screen. Which screener is suit for domestic waste separation? Domestic waste refers to…