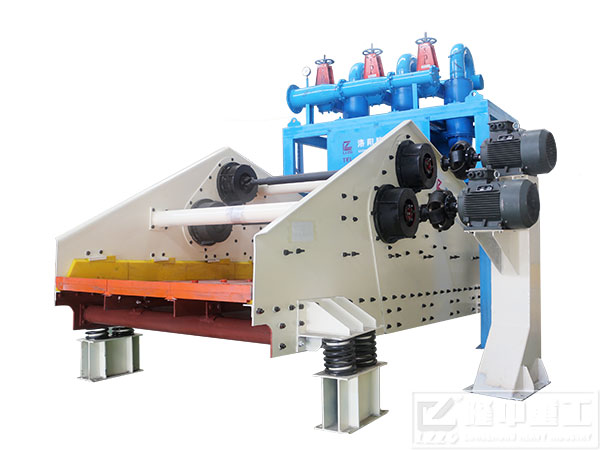

Vibrating screen, hydrocyclone desander for removing silt from drilling fluid

July.09,2019

July.09,2019

The mechanical mud desander mainly has a vibrating screen. The mud passes through the vibrating screen to destroy the structure of the mud, so that the cuttings and sand slide down from the sieve, and the mud flows out from the sieve.

The sandstone vibrating screen uses the vibration exciter as the vibration source, and the high-efficiency soft link device is applied. When the equipment works to generate vibration, the equipment is protected. The unique structure screen will not be blocked, and the tilt of the screen surface of the equipment can be Adjusted by a unique adjustment device, the service life is greatly improved, resulting in high practical value.

Sand and gravel sieve can sift many materials, such as ore, aluminum powder, copper powder, sand, ore, alloy powder, sand, stone, abrasive powder, refractory material, limestone, quartz sand, and other materials.

The hydraulic mud desiler has a mud cyclone desander, which first pumps the mud into a funnel container by a sand pump. The pumping direction is directed along the tangential line to the inner wall of the container. The slurry is rotated by centrifugation, the structure is destroyed, the cuttings and sand are discharged from the funnel, and the mud flows out from the upper opening of the container. The mud cyclone desander has better sand removal effect than the vibrating screen and is widely used in deep well drilling.

The working principle of the sand remover:

The hydro-cyclone desander is based on the principle of centrifugal sedimentation and density difference. When the water flow is under a certain pressure, the inlet of the desander is tangentially entered into the equipment, and a strong rotational motion is generated. Due to the different sand water density, the centrifugal force, Under the action of centripetal buoyancy and fluid drag, the low-density clear water rises and is discharged from the overflow port. The dense sand is discharged from the bottom discharge port to achieve the purpose of sand removal. Under certain ranges and conditions, the greater the water inlet pressure of the desander, the higher the sand removal rate, and multiple units can be used in parallel.

Desander use

When selecting the type of desilter, the desilter should allow a maximum of 1.25 times the maximum displacement of the drilling fluid. The drilling fluid entering the desilter must be processed by a vibrating screen and a desander.