Placer gold trommel screen with low energy consumption

November.05,2019

November.05,2019

Mineral processing equipment for placer gold sand

Similar to sand tin mines, gold deposits are deposited on hillsides, riverbeds, and shores of lakes, forming a certain enrichment. Those with industrial exploitation value are called sand gold deposits. Under normal circumstances, the sand gold ore has a high degree of dissociation. It is only necessary to use a trommel screen to screen out a large piece of waste stone that does not contain gold. The gold deposit is left on the sticky gold cloth and can be obtained very well. index.

The working principle of the drum screen

The trommel is a commonly used sieve for beneficiation and is used before the sorting process. Through the continuous rotation of the drum screen, large pieces of waste rock can be thrown out, which can save the time of sorting operation and greatly improve the sorting operation in the next step. The motor is coupled to the roller unit by coupling through the coupling to drive the roller unit to rotate about its axis. The trommel is a mechanical method in which a plurality of parallel sieve bars forms a sieve opening to form a screen surface. After the material is placed in the roller device, due to the tilting and rotation of the roller device, the material is turned over and rolled, and the materials are screened out one by one through different mesh screens, and the material stuck in the mesh hole can also be ejected to prevent clogging.

Roller screen application

The drum screen avoids the problem of the screen sticking of the vibrating screen when screening the wet materials, and improves the output and reliability of the screening system. It is suitable for screening large blocks of materials, gold mines, as well as coal, coal gangue, coke raw slaked lime and other wet and easy to block materials, especially for sand gold mines, sand tin mines and other screening, has a better effect.

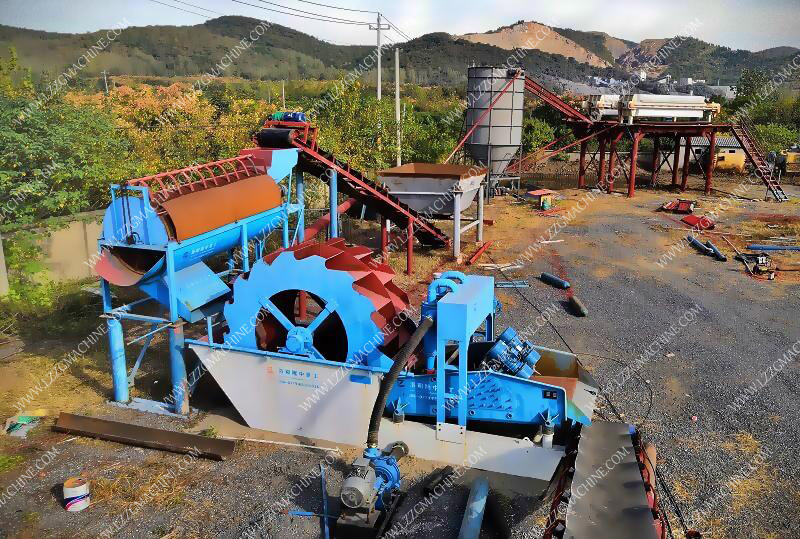

trommel screen in sand washing plants

LZZG drum screen advantages

1. Adopting the principle of rolling conveying, the friction coefficient is small, the wear is light, and the mesh hole is not blocked.

2. The roller support adopts the integral through-shaft structure, which runs smoothly, does not vibrate, and has low noise.

3. The internal drum screen accessories adopt the split design, the structure is simple, and the replacement and repair are quick and convenient.

4. The operation is safe and reliable, with low power, low energy consumption and an obvious energy-saving effect.

5. One-time investment, small investment funds, large processing capacity (daily processing capacity of several thousand tons), the recovery is particularly high.

6. As long as there is silica sand there is gold sand, the equipment is lightweight, easy for move mining.