Methods for efficient ore washing

According to the characteristics of different ores, choosing suitable washing equipment can improve the washing efficiency. Hydraulic ore washing screen The ore washing method using a water gun to wash…

published date: 02-25-2019

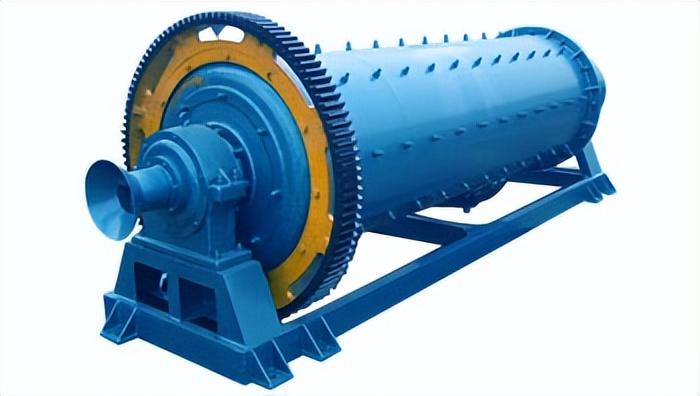

As a common stone washing equipment, the spiral stone washing machine and the large amount of sand and gravel de-sludge and screening operations by hydropower, can also be used for ore sorting operations, and have been widely used in engineering and other fields!

The spiral stone washing machine can separate the dirt and ash powder on the material into clean materials. The machine has the advantages of simple structure, easy maintenance, and high washing efficiency.

The copper ore spiral washing machine is composed of a tank body, a speed reducer, a motor, a central shaft, a spiral blade, and a bracket. The bracket is welded on the central shaft, and the spiral blade is mounted and then pressed with bolts so that the blade does not sag and does not deform.

The dust and impurities are separated from the sand and passed through the spiral blade to achieve the purpose of filtering the water to remove impurities. The machine rotor adopts a central structure, and the spiral blade is mounted on the central shaft and is connected to the central shaft by the reducer for work. An apparatus for mechanical classification by virtue of the fact that the specific gravity of the solid particles is different and thus the rate of sedimentation in the liquid is different.

Flotation of disseminated copper ore generally adopts a relatively simple process. After a period of grinding, the fineness-200 mesh accounts for 50%~70%, 1 rough selection, 2~3 times selection, 1 ~2 sweeps. If the particle size of the copper mineral is relatively fine, a stage grinding process may be considered. Most of the concentrating plants that deal with the porphyry ore are re-grinding with coarse concentrates – a selective stage grinding process, which is essentially a mixing-priority flotation process. After a rough grinding, rough selection, sweeping, and then re-grinding the coarse concentrate to obtain a high-grade copper concentrate and sulfur concentrate. Rough grinding fineness – 200 mesh accounts for about 45% to 50%, and regrind fineness – 200 mesh accounts for about 90% to 95%.

Our company is a manufacturing enterprise mainly engaged in the production of mining machinery and ore washing equipment. The main products are: stone washing machine, sand washing and recycling machine, drilling mud cleaning equipment, vibrating screen, etc. Our company has professional mineral processing equipment. Experts can provide users with services such as mineral ore washing plant and mineral processing production line design and planning.

According to the characteristics of different ores, choosing suitable washing equipment can improve the washing efficiency. Hydraulic ore washing screen The ore washing method using a water gun to wash…

The main equipment needed for the copper ore beneficiation process. 1. Vibrating feeder Vibrating feeder is also called vibrating feeder. In the production process, it can evenly, punctually and continuously…

Iron ore washing instruction Ore washing is the gravity dressing process used to treat ore that is cemented with clay or contains much mud. Mainly the process of separating materials…

Stone washing machine, also called sand washing machine (or gravel washing machine), is used for desliming and screening of sand and gravel at construction sites and sand and gravel plants.…