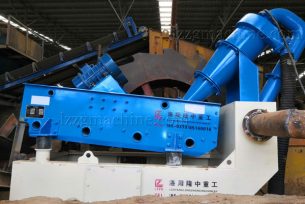

Highly efficient hydraulic classifier for fine particle materials

The LSF series wet hydraulic classifier is the most advanced fine particle materials classification equipment (based on gravity separation) with significant advantages in capacity, adaptability and efficiency. It is suitable for grading ultra-fine materials from 10 to 100 mesh. LSF adopts a new “laminar flow high shear rate” mechanism, which is the latest fine particle gravity separation technology. Traditional technologies cannot adapt to changes in feed particle size, resulting in recovery losses, while LSF is much more tolerant of changes in feed particle size. Therefore, it has higher recycling and classification efficiency.

Working principle

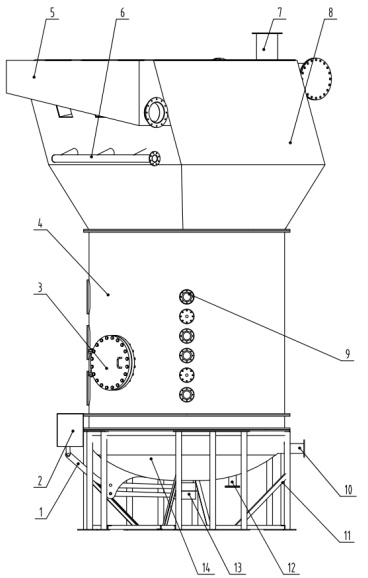

LSF classifies small particles based on differences in density or particle size. LSF combines a traditional fluidized bed separator with a set of parallel inclined plates that form thin plate channels. Fine-grained materials enter the inside of the thin plate cavity through the feed port, and then enter the mixing chamber below the thin plate. The materials are fluidized under the action of the fluidized bed to form a slurry. Materials with high density will sink due to gravity, while materials with low density will float.

Application scenarios

Hydraulic classifier can be used in mining, aggregate processing, piling mud, river dredging, coal slime sorting, photovoltaic quartz sand raw material production and processing, ceramic raw material processing, silica sand production and processing, fracturing sand production and processing, and various metal mine tailings treatment. In projects where the screening and recovery of fine-grained sand and gravel, the classification and mud removal effect are poor, the equipment space is occupied, and the investment is large.

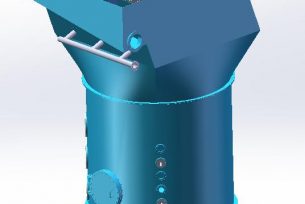

1. Unloading device 2, air rod 3, observation port 4, mixing chamber 5, discharge chamber 6, impurity filter port 7, feed port 8, separation chamber 9, monitoring window 10, clean water port 11, bracket 12 , drain port 13, cylinder 14, liquefaction chamber

Product Features

1. Can be configured according to specific requirements on site;

2. Easy to install, pack and transport;

3. Easy to adjust, providing greater process flexibility and higher efficiency;

4. Compact structure, easy to operate and suitable for any production line layout;

5. Use advanced instrumentation and controls to monitor all process parameters to ensure optimal performance, achieve more consistent operations through automation, and improve recycling efficiency;

6. Reduce maintenance costs, More environmentally friendly;

7. suit for 10mesh to 300 mesh fine particle screening

Technical parameters

| Model | Feeding particle size (mm) | Processing capacity (t/h) | Outline dimensions (mm) |

| LSF 1100 | 0.04~2 | 40 | 4134*1987*6126 |

| LSF 2000 | 0.04~2 | 100 | 4847*2845*6234 |

| LSF 3000 | 0.04~2 | 200 | 6456*3665*6915 |

| LSF 3600 | 0.04~2 | 300 | 7280*4484*7525 |