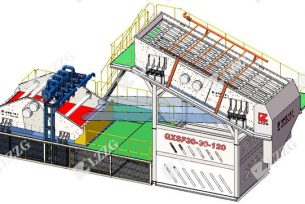

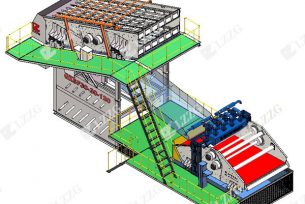

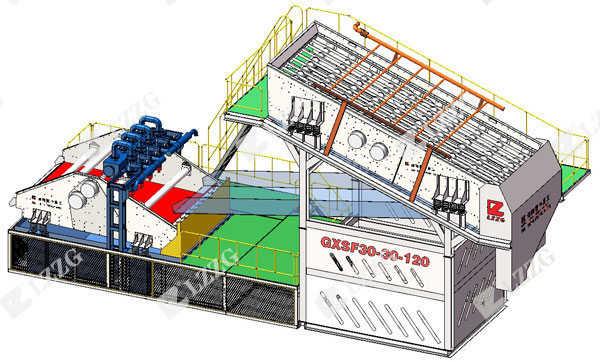

Modular screen plant with fines recovery unit

The modular screening plant is used for screening, dewatering, and fine material recovery of aggregates, piling mud, and silica sand. The machine has a compact structure, small footprint, can be quickly installed and moved, and can quickly start working. Combined with crusher and sand washer, used in sand factory and metal ore production.

Working principle

The artificial sand or natural sand is fed to the vibrating screen through a belt, and water is added to the sieve plate to rinse. The materials are screened under the action of vibration and gravity, and the materials under the screen are transported to the dewatering screen through the under-screen water tank and flow tank. Carry out dehydration and recovery operations. At the same time, sticky gold blankets or magnetic separators can be laid in the flume to extract valuable components from the materials and improve economic efficiency.

Product Features

- The overall use of three-dimensional layout, the layout is reasonable and beautiful.

- Screening is effectively combined with water washing, recycling and dehydration. It is suitable for materials with low mud (powder) content.

- During the screening and dehydration process, sticky gold blankets or magnetic separators can be laid to extract valuable components from the materials and improve economic efficiency.

- Integrated design, with perfect frame structure and fluid pipeline design, easy installation and maintenance.

Technical parameters

| Model | Feed Size(mm) | Capacity(t/h) | Screen Unit(mm) | Dewater Unit(mm) | Hydrocyclone(mm) | Power(kw) | Weight(kg) | Overall Size(mm) |

| GXSF18-18-100 | ≤10 | 60-100 | 1800*6000 | 1800*4800 | 250*4 | 74 | 15000 | 14000*4500*6800 |

| GXSF24-24-120 | ≤10 | 80-120 | 2400*6000 | 2400*4800 | 300*4 | 126 | 21000 | 14000*5000*7400 |

| GXSF30-30-140 | ≤10 | 80-120 | 3000*7200 | 3000*6000 | 350*4 | 171 | 28000 | 16000*5530*7900 |

| GXSF36-36-180 | ≤10 | 120-180 | 3600*7200 | 3600*6000 | 300*6 | 194 | 35600 | 16000*6100*8600 |