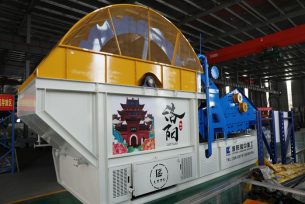

High-efficiency energy saving cyclone sand washing plant

Adopting cyclone sand washing technology and precise fluid dynamics design. The cyclone can generate a strong centrifugal force field in high-speed rotation, quickly and efficiently separating sand and gravel from soil and impurities. The sand washing efficiency is greatly improved compared with traditional equipment.

Integrated installation structure, grid-type walkway, fully spliced guardrail, convenient and flexible. The maximum size of the design components is designed in accordance with standard containers and can be packed and shipped to all parts of the world.

Working principle

The working principle of the hydrocyclone is mainly to use centrifugal force for classification. The slurry enters the cyclone shell through the feed pipe under pressure. The coarse particles or particles with high density enter the periphery of the rotating flow due to the large centrifugal force, and finally discharged from the bottom sand settling nozzle to become sand; the fine particles are subjected to a smaller centrifugal force, are in the center of the rotating flow and move upward with the liquid flow, and finally discharged from the overflow pipe to become overflow.

Product Features

PLC intelligent design, highly automated.

The scrubbing machine uses corundum ceramic lining, and the wear resistance is increased by 2 times.

Use large-diameter cyclone to further clean machine sand, quartz sand, and river sand.

The whole machine provides a three-year warranty and free maintenance.

The cyclone uses 95 wear-resistant ceramic as the lining material, and its wear resistance is 10-26 times that of ordinary steel and 5-8 times that of polyurethane.

The high-frequency ultrasonic sounder generates countless tiny bubbles through high-frequency vibration when the slurry rotates with the scrubbing shaft. When the bubbles burst, they will generate a certain amount of energy, which can make the impurities on the surface of the material particles or in the gaps fall off and be discharged with the sewage, thereby achieving a better scrubbing effect.

Technical parameters

| Model | Capacity m³ | Scrubbing specifications (mm) | Cyclone specifications (mm) | Dewatering screen specifications |

| XS50 | 50 | CX2-1 | 550 | 1530 |

| XS100 | 100 | CX2-2 | 660 | 1848 |