Linear Vibrating Screen Models

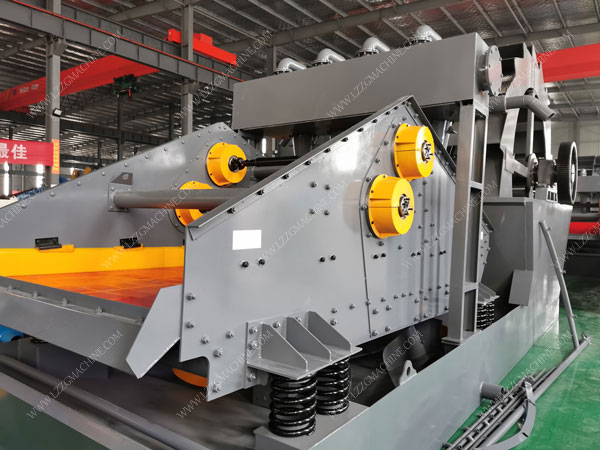

Linear-motion vibrating screen uses vibrating motor as the vibration power source. The material is thrown up on the screen and moves forward in a straight line. Materials enter the feeding port of the screening machine evenly from the feeder and generates the number through the multi-layer screen. Our factory produces various types of linear motion vibrating screens.

The sieves and sieves of various specifications are discharged from the respective outlets. The utility model has the advantages of low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust overflow, automatic discharging, and is more suitable for pipeline operation. The tailings linear vibrating screen is mainly used for dehydration of iron ore, copper ore, gold ore, and aluminum mine tailings.

Working principle

The linear vibrating screen is driven by a double exciter. When the two exciters are synchronized and reversely rotated, the exciting force generated by the eccentric block cancels each other in a direction parallel to the motor axis, in a direction perpendicular to the motor shaft. The stack is a combined force, so the movement of the sieve machine is a straight line. The two motor shafts have an inclination angle with respect to the screen surface. Under the combined force of the excitation force and the material self-gravity, the material is thrown up and jumped forward in a linear motion on the screen surface, thereby achieving the purpose of screening and classifying the materials.

Product Features

1. High working frequency, high vibration intensity, low moisture content on the sieve, high unit processing capacity, and high solid recovery when used for tailings dewatering.

2. Using the self-synchronization principle, the motor drives the vibrator through the tire coupling, which has a simple structure and low working noise.

3. Installation with negative dip angle, the screen surface of the dewatering section is installed at 45 degrees with the horizontal, increasing the dewatering area and promoting the dehydration of the material as soon as possible to form a filter layer.

4. In order to adapt to the difference in properties of different tailings, the amplitude of the sieve can be adjusted. The method is to adjust the angle between the main and auxiliary eccentric blocks to meet the dewatering effect of tailings with different properties, and strive to achieve excellent process results.

5. The side plate and the beam are connected by torsion-shear type high-strength bolts, and there is no weld seam, which avoids the problem of side plate cracking caused by welding stress.

6. The vibrator is a block eccentric unit structure, which is easy to disassemble and maintain.

7. The bearing adopts special bearing for vibration equipment to avoid premature damage of bearing heat.

8. The mesh surface adopts polyurethane elastic screen surface, high opening ratio and elasticity, which is beneficial to dehydration.

Technical parameters

| Model | Motor power (kw) | Separator Specifications | Processing amount (m3/h) | The amount of sand released (t/h) | Feed size (mm) | sieve board parameters | machine weight (kg) | Dimensions (mm) include pumps and motors | |

| Dewatering screen size (mm) | Sieve material | ||||||||

| GP1530J-65 | 36 | FX300*2 | 120-180 | 80-120 | ≤10 | 1500*3000 | Polyurethane | 3500 | 3250*5560*3000 |

| GP1836J-75 | 48 | FX350*2 | 160-240 | 100-140 | ≤10 | 1800*3600 | Polyurethane | 5600 | 4000*5560*3520 |

| GP1842J-100 | 59 | FX250*4 | 200-280 | 100-140 | ≤10 | 2400*4200 | Polyurethane | 6120 | 4600*5560*3520 |

| GP2442J-100 | 59 | FX250*4 | 200-280 | 140-180 | ≤10 | 2400*4200 | Polyurethane | 7961 | 4600*6050*3600 |

| GP2448J-120 | 90 | FX300*4 | 240-360 | 140-180 | ≤10 | 2400*4800 | Polyurethane | 8830 | 5220*6050*3600 |

| GP3048J-140 | 104 | FX350*4 | 320-480 | 180-250 | ≤10 | 3000*4800 | Polyurethane | 9636 | 5010*7860*3720 |