3 layer vibrating screen for sand aggregate separation

High capacity fine and coarse aggregate classification machine

Y series multilayer circular vibrating screen is high efficient sand vibrating screen. It filter materials into multiple grades according to the size. For the compact structure and the convenient installation, it is the ideal screening device for prefilter of the feed materials before the primary crushing in the quarry site, it also can be used as separation and filtration solely. The vibrating screen adopts cylinder type eccentric shaft vibrator and partial block to adjust the amplitude. The material sieve drip line is long and more sieving specifications.

Application field: production classify in the silica sand production, quarry, mine, construction, electricity, chemical industry, etc.

Working principle of vibrating sifter

The circular vibratory screen uses the vibrrating motor to drive the eccentric shaft to make the screen body periodically along with the direction of vibration force. The materials do circular movement on the screen to realize sieving.

The series of circular vibrating screens are mainly composed of a sieve box, a screen, a vibrator, and a vibration-damping spring. The vibrator is mounted on the side plate of the screen box and is rotated by the motor through the V-belt to generate centrifugal inertial force, forcing the screen box to vibrate.

This series of screens is mounted in a seat. The adjustment of the screen inclination can be achieved by changing the height of the spring support. The motor can be installed on the left side of the screen frame, and can be installed on the right side of the screen frame. If there is no special requirement, the manufacturer installs the product according to the right side of the material movement direction.

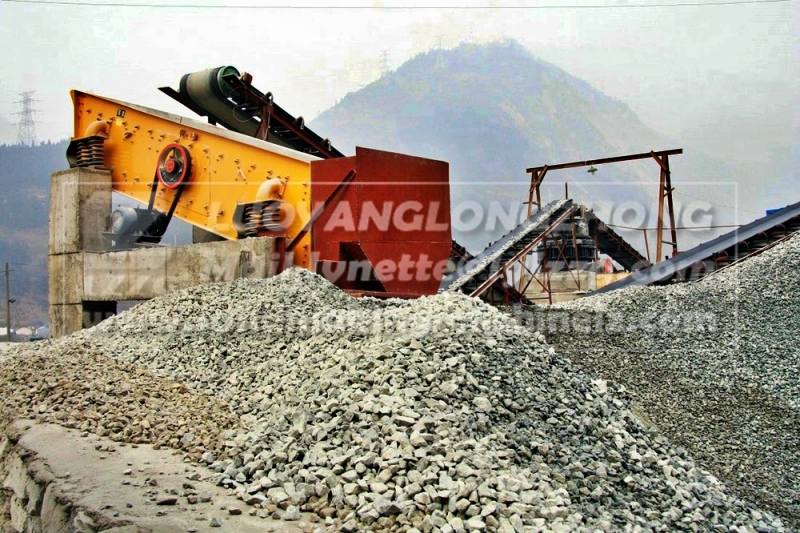

circular screening machine in sand washing plant

Product Features

1. Vibrating screen YA is of double decks to four decks whose moving track is round.

2. The moving track of material is very long; the size of material can be separated into several specifications.

3. It adopts cylinder style inspiring vibrator device and eccentric shaft to adjust. It has the features of reliable structure, strong vibrating generation, high screening efficient, low noise, easy maintenance, safe performance, etc.

4. It is widely used in separating gravel and is also suitable for mining, construction material, transportation, energy, chemical industry and so on.

Customized screen

According to the different needs of users, the series of vibrating sieve screens can be equipped with wire mesh woven mesh, rod, casting, welding, punching and other forms of screen surface to meet the needs of different industries. If the user has no special requirements, the Y and 2Y types are textile screen surfaces, and the YH type is the punching screen surface. All kinds of screen surfaces can meet the requirements of high screening efficiency, long service life and no hole blocking.

Technical parameters

| Model | Feed size (mm) | Capacity (t/h) | Screen size (mm) | Single-layer screen area (m2) | Power (kw) | Dimensions (mm) |

| 2YK1548 | 0-200 | 0-160 | 1500X4800 | 7.2 | 11 | 5000X2900X2900 |

| 2YK1860 | 0-200 | 0-200 | 1800X6000 | 10.8 | 15 | 6200X3400X3500 |

| 3YK1860 | 0-300 | 0-200 | 1800X6000 | 10.8 | 22 | 6200X3400X4100 |

| 2YK2160 | 0-200 | 0-250 | 2100X6000 | 12.6 | 22 | 6200X3700X3500 |

| 3YK2160 | 0-300 | 0-250 | 2100X6000 | 12.6 | 22 | 6200X3700X4100 |

| 2YK2460 | 0-200 | 0-300 | 2400X6000 | 14.4 | 22X2 | 6200X4100X3800 |

| 3YK2460 | 0-300 | 0-300 | 2400X6000 | 14.4 | 30X2 | 6200X4100X4400 |

| 2YK2472 | 0-200 | 0-300 | 2400X7200 | 16.8 | 22X2 | 7400X4000X4000 |

| 3YK2472 | 0-300 | 0-300 | 2400X7200 | 16.8 | 30X2 | 7400X4100X4600 |

| 2YK3072 | 0-200 | 0-300 | 3000X7200 | 21.6 | 30X2 | 7400X4700X4100 |

| 3YK3072 | 0-300 | 0-300 | 3000X7200 | 21.6 | 30X2 | 7400X4700X4700 |

| 3YK3672 | 0-300 | 0-350 | 3600X7200 | 25.92 | 37X2 | 7400X5400X4700 |