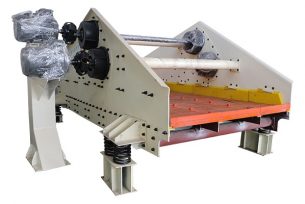

Linear Motion Drying Shaker for Drilling Fluid

Cleaner fluids with a small footprint

LZZG provide higher efficient linear motion drying shakers to ensure a fast and efficient turnaround time on your fluid recovery process. Linear motion shale shakers meet the needs of solids separation in a large number of different industries. Such as Dredging, Mining, and Dewatering for waste disposal, oil and gas drilling.

Working principle

The drilling fluid drying shaker is based on the eccentric mass of the vibrating motor and generates linear motion, circular motion or translational elliptical motion trajectory through the shock beam transmission. In the two motors, the vertical line and the screen angle are in the a-angle or linear mode, so that the two excitation motors rotate in the opposite direction, and the mutual vibration generates the exciting vibration force. The mud is continuously thrown down and moved forward, the mud The liquid leaks into the mud tank through the screen, and a part of the solid particles in the mud and the mesh holes are sieved out, thereby purifying the mud liquid.

Product Features

1. High efficiency, strong vibrating force, and large capacity.

2. Simple structure and easy operation and maintenance.

3. 45°angle install increases the dewatering area.

4. Vibrating frequency is adjustable to meet different ores.

5. Torsional shear type high strength bolts are used between side plates and beam. No weld gap avoids side plates cracking during vibrating.

6. Polyurethane screen with better elasticity and fewer blocks. The PU side push plates protect the equipment from the rushing material and guard the long life of the whole device.

7. Vibrating screen: The mud vibrating screen can be replaced in a few minutes. Each screen has a much longer lifespan.

8. The most simple and easy to maintain.

Technical parameters

| Model | Motor power (kw) | Cyclone | Capacity (m³/h) | Production (t/h) | Feed size (mm) | Screen parameter | Weight (kg) | Dimension (mm) | |

| Screen size(mm) | Screen material | ||||||||

| GP1530J-65 | 3.0*2 | 300*4 | 120-180 | 80-120 | ≤10 | 1500*3000 | PU | 3500 | 3250*5560*3000 |

| GP1836J-75 | 5.5*2 | 350*2 | 160-240 | 100-140 | ≤10 | 1800*4300 | PU | 5600 | 4000*5560*3520 |

| GP1842J-100 | 7.5*2 | 250*4 | 200-280 | 100-140 | ≤10 | 2400*3700 | PU | 6120 | 4600*5560*3520 |

| GP2442J-100 | 7.5*2 | 250*4 | 200-280 | 140-180 | ≤10 | 2400*4200 | PU | 7961 | 4600*6050*3600 |

| GP2448J-120 | 15*2 | 300*4 | 240-360 | 140-180 | ≤10 | 2400*4800 | PU | 8830 | 5220*6050*3600 |

| GP3048J-140 | 15*2 | 350*4 | 320-480 | 180-250 | ≤10 | 3000*4800 | PU | 9636 | 5010*7860*3720 |