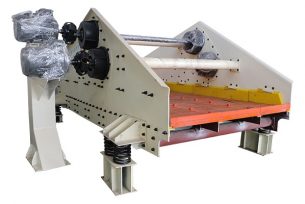

Mud shale shakers

Drilling fluid shale shaker is used for the first-level solid-control equipment of drilling mud purification system. It adopts imported excitation motor, which is suitable for oil drilling fluid purification single, double or triple. At the same time, drilling fluid vibrating screen can also be used for mud cleaner. For bottom flow vibrating screens. The drilling fluid vibrating screen has the advantages of high vibration intensity, large screening area, adjustable screen box angle, compact structure and excellent performance.

Working principle

Under the action of the eccentric mass, the vibrating screen motor generates a linear motion, a circular motion or a translational elliptical motion trajectory through the shock beam transmission. In the two motors, the vertical line and the screen angle are in the a-angle or linear mode, so that the two excitation motors rotate in the opposite direction, and the mutually excited vibrational forces are mutually offset in the X direction, and the exciting force is zero. In the Y direction, the exciting forces of the two motors superimpose each other to drive the reciprocating motion of the entire upper and lower screen boxes along the Y-axis direction, and at the same time, the mud on the screen surface is thrown along the Y-axis direction, and then the free-falling direction has been Moved forward, so that it is continuously thrown down and moved to move the mud forward. The mud liquid leaks into the mud tank through the screen and the solid particles in the mud and the mesh holes are screened out, thus purifying the mud. effect. Drilling fluid vibrating screen is used to treat slurry solid particles above 74μm from the bottom of the well.

Product Features

1. The angle adjustment of the electric screen box is convenient and reliable, and the mechanical angle adjustment is used for standby.

2, screen box sealing patent design, good sealing effect, long service life, and easy to replace.

3. The bottom frame of the screen box is made of stainless steel, which greatly improves the corrosion resistance and life.

4. The overall heat treatment of the screen box can meet the long-term work under high excitation intensity.

5, plate frame net, plus wedge type screen pressing device, easy to change the screen quickly.

6, using international brand vibration motor, Martin motor or OLI motor.

7, international famous brand electrical components, Siemens or Schneider components.

8, a variety of feeding mode, convenient for different occasions: back-type logging tank, overhead logging tank, funnel-type feeding box.

Technical parameters

Mud vibrating screen structure The drilling fluid vibrating screen is mainly composed of a base, a sieve box, a sieve plate net, a mud liquid inlet tank, a vibration motor, a shock absorbing spring, a control switch and the like. The base is used for fixing the foundation screw; the support members (bracket and motor support) are used to support the screen box and the motor; the support spring is used for amplitude generation, and the vibration motor (vibrator) is the more important component on the vibrating screen. As the power source of the vibrating screen, the vibrating screen is brought to the required vibration amplitude. screen plates are fixed and adjusted by snap-on bolts and hook tensioners, so that the combination of horizontal and vertical support rods can provide sufficient strength for the screen basket.