Wear-Resistant trommel screen with feed hopper for sale

September.23,2019

September.23,2019

High-quality trommel screen with feed hopper

A compound fertilizer equipment drum screening machine was used in the production of compound fertilizer. It is mainly used for the separation of finished products and return materials. It can also realize the classification of finished products and make the finished products evenly classified. The combination screen is convenient for maintenance and replacement. The machine has a simple structure, convenient operation, and stable operation.

How does the trommel screen work?

The trommel screen mainly consists of a motor, a reducer, a trommel set, a frame, a sealing cover, inlet, feed hopper, and outlet. The rotary screen assembly is mounted obliquely on the frame, and the motor is coupled to the rotary screen through the coupling through the reducer to drive the trommel assembly to rotate about its axis.

When the material enters the trommel screen device during the quarry screen operation, due to the inclination and rotation of the trommel assembly, the material on the screen surface is turned over and rolled, so that the qualified material (the product under the screen) is discharged through the bottom of the rear end of the trommel. The mouth is discharged, and the unqualified material is discharged through the discharge port at the tail of the trommel. Due to the turning and rolling of the material in the trommel, the material stuck in the screen hole can be ejected to prevent the screen hole from being clogged.

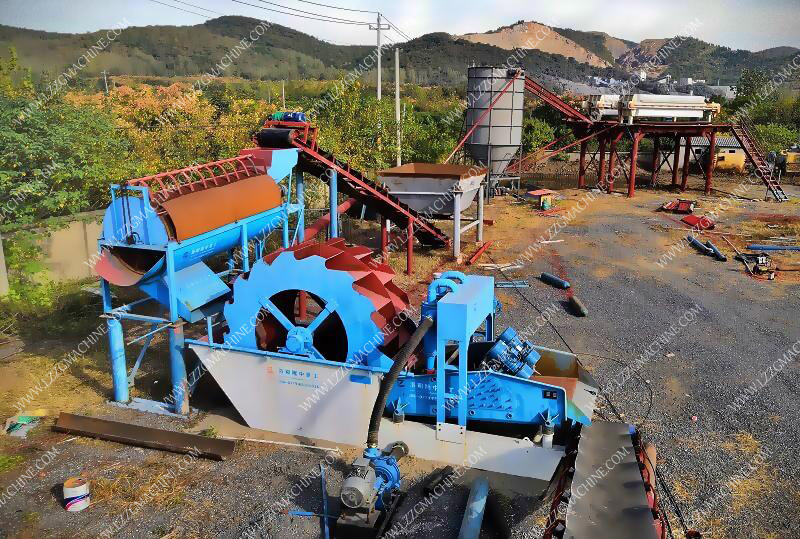

lzzg trommel screen for materials separation

Application

The rotary screen is sieved by gravity centrifugal force. Material suitable for the drum screen:

Stone yard for grading of large and small stones, and separation of soil and stone powder.

Coal industry for the separation of lump coal and pulverized coal and coal washing (part of coal washing machinery)

Grading and separating powdery materials

For urban waste sorting

Building materials

Coal preparation

fertilizer

Topsoil

Glass

Technical parameter of Trommel Screen

| Model | Sceen size (m) | Angle (°) | Rotational speed (r/min) | Mesh size (mm) | Max feeding size (mm) | Capacity (t/h) | Power (kw) | Weight (kg) | Dimension (mm) |

| GT1030 | φ1.0*3.0 | 6 | 22 | 5-15 | ≤40 | 30-100 | 4 | 1300 | 4500*1358*2336 |

| GT1040 | φ1.0*4.0 | 6 | 22 | 5-15 | ≤40 | 30-100 | 4 | 1500 | 5500*1458*2336 |

| GT1230 | φ1.2*3.0 | 6 | 22 | 5-15 | ≤40 | 30-150 | 5.5 | 1500 | 4500*1585*2478 |

| GT1240 | φ1.2*4.0 | 6 | 22 | 5-15 | ≤40 | 30-150 | 5.5 | 1700 | 5500*1685*2478 |

| GT1540 | φ1.5*4.0 | 6 | 17 | 5-15 | ≤40 | 30-200 | 7.5 | 2500 | 5800*2100*4400 |

| GT1560 | φ1.5*6.0 | 6 | 17 | 5-15 | ≤40 | 30-200 | 11 | 2700 | 6800*2200*4400 |

| GT1860 | φ1.8*6.0 | 6 | 11 | 5-15 | ≤40 | 30-250 | 18.5 | 5010 | 8486*2100*4673 |

| GT2160 | φ2.1*6.0 | 6 | 10 | 5-15 | ≤40 | 30-250 | 22 | 6360 | 8486*2500*5000 |

| GT2460 | φ2.4*6.0 | 6 | 9 | 5-15 | ≤40 | 30-300 | 22 | 7000 | 8486*2860*5200 |

| GT2480 | φ2.4*8.0 | 6 | 8 | 5-15 | ≤40 | 30-300 | 22 | 7500 | 8700*2860*5700 |

Service

As long as the customer needs, we will be in contact with you for the first time, to understand the specific needs of customers, material components, scheduled worksite, and other related information, to help customers analyze problems, solve problems.