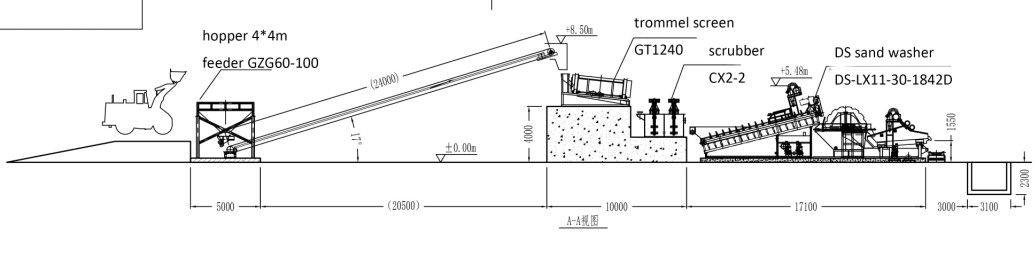

300 tph wear-resistant and easy to operate sand washing production line

January.21,2025

January.21,2025

Recently, Longzhong built a 300 tons per hour environmentally friendly sand washing sewage treatment project for a Jiangsu enterprise. At present, all installation and construction have been completed, and it is expected to be officially put into operation in early April this year.

Product features:

The raw materials of this production line are pebbles, granite, and mountain sand. From crushing and sand making, screening and washing, zero sewage discharge, and storage, all links adopt a fully enclosed structure, and the dust collection pipeline is arranged at various dust points in the system to avoid dust spillage and achieve environmentally friendly production.

In order to extend the service life of the equipment, the company uses thickened wear-resistant steel to manufacture sand washing machines, vibrating screens, high-quality polyurethane screen plates, and polyurethane cyclone linings. The durability of the equipment is greatly improved.

The equipment adopts a compact design, which reduces the floor space and intelligent operation, making the production line management simple.

Project Overview

Project capacity: 300t/h

Processing materials: machine-made sand after crushing and screening

Equipment configuration: double-wheel sand washing and recycling integrated machine, three-hydrogen purification body, chamber filter press, etc.

Treatment process: front-end sand washing, back-end sewage treatment

Finished material use: can be used for infrastructure construction and standard sand needs