LZZG Uzbekistan Silica Sand Purification Production Line

January.15,2025

January.15,2025

Longzhong Silica Sand (Quartz Sand) Purification Production Line Process

For the quartz sand finished product requiring a particle size of 20-140 mesh (0.1-0.85mm), preliminary screening, cleaning, iron removal, dehydration, drying, fine screening, and tail water recycling and reuse are first carried out.

According to customer needs, one or more combinations of these can be used to remove impurities in the quartz sand to achieve purification requirements.

Silica Sand Purification Process:

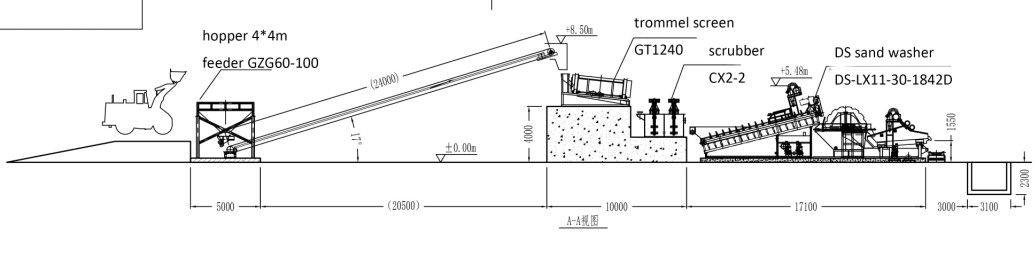

1. Quartz sand screening (impurity removal)

The raw materials are conveyed to the drum screen or circular vibrating screen by a belt conveyor for impurity removal. A spray device is added to screen out impurities such as branches, leaves, shells, stones, etc., and the mud is removed preliminarily;

2. Quartz sand cleaning (recycling)

The screened raw materials flow into the scrubber by gravity. The scrubber uses a motor to drive the main shaft to rotate at high speed. The speed is about 300-380r/min. The inner wall and impeller of the cylinder are all made of polyurethane, and a polyurethane flow plate is set on the inner wall of the cylinder to ensure that no iron-containing substances are mixed into the material during the water washing process. When the impeller rotates at high speed, the materials will rub against each other, which can clean the dirt and oxides on the surface of the sand and gravel particles;

3. Iron removal (magnetic separation)

After the washed quartz sand, a magnetic separator can be configured to remove iron to meet the iron content standard required for the finished sand. The iron-containing concentrate after magnetic separation is sent to the designated location by a chute or belt conveyor.

4. Sand drying + fine screening process

Using the equipment dryer, the high-purity quartz sand after impurities removal can be dried and then packaged into finished products.

The dried material can be packaged directly or finely screened in the next step to achieve finished sand of various particle sizes.

5. Tail water zero discharge system process

In view of the muddy tail water discharge and environmental protection requirements of the cleaning process, our company has launched a complete tail water recovery system.

The Uzbek customer highly appreciated the Longzhong Mine equipment and process flow, and signed a contract for the quartz sand purification production line on the spot, covering screening, cleaning, iron removal, drying, and fine screening EPC general package.