The LZZG sand mining processing plant is equipped with sand washing and sewage treatment equipment. It can save 80% of sand washing water for customers, and the processing capacity of the sand making machine can reach 50 to 300t/h. This sand washing production line has high output, low maintenance cost, and low energy consumption Etc.

Rock sand processing equipment

Granite, limestone, quartz stone sand making equipment includes jaw crusher, impact crusher (sand making machine), vibrating screen (circular vibrating screen), sand washing machine, sewage thickener, chamber filter press or belt press Filter, belt conveyor.

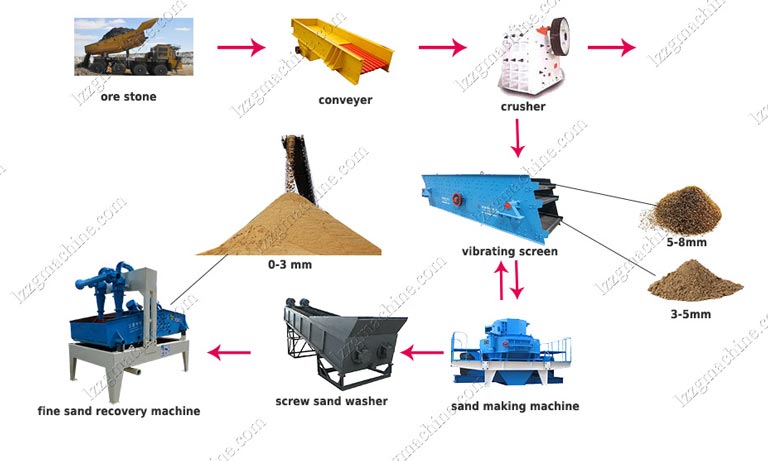

Process of sand making plant

1 primary coarse

The vibrating feeder uniformly conveys the machined sand material to the jaw crusher through the silo for coarse crushing. The coarsely crushed material is sieved by the vibrating screen, and then sent to the impact crusher or cone crusher by the belt conveyor Perform secondary crushing;

2. Intermediate crushing

After the finely crushed river pebbles in the cone crusher, after screening through the circular vibrating screen, the larger particles are returned to the crushing equipment and crushed again;

3. Sand making

Transfer the crushed river pebbles to the sand making machine for further crushing and shaping. Then it is classified into coarse sand and fine sand by circular vibrating screen.

4. Sand washing

Mechanical sand discharged from the sand making machine is sent to the sand washing machine for cleaning, and then enters the dehydration sieve for dehydration and drying. The sand washing tail water passes through the concentration tank and is used for sand washing after purification by the filter press.

5. Packaging

The dehydrated sand is stored and packaged.

Construction waste crushing and sand making system

The crushed stone sand processing line has the following features

High-efficiency energy saving cyclone sand washing plant

Rake thickener

Highly efficient hydraulic classifier for fine particle materials

High efficiency silica sand classification spiral concentrators