What do I do if I do n’t understand the equipment and technology when investing in a sand and gravel production line? For sand and gravel factories that have just entered the industry, small mining equipment is often preferred to produce sand and gravel aggregates. Then how is the most cost-effective configuration of a small sand and sand production line with an output of 30 tons per hour? What is the approximate price? Longzhong Heavy Industry Machinery Co., Ltd. introduces a small sand and gravel production line equipment configuration guide.

Applicable materials: river pebbles, pebbles, bluestone, granite, basalt, limestone, cement clinker, marble, iron ore and other more than 200 kinds of ore materials.

High hardness rock: jaw crusher (coarse crushing first crushing), cone crusher (medium-fine crushing), and auxiliary equipment such as raw material silo, vibrating feeder, belt conveyor, circular vibrating screen. Suitable for granite, tablets Hemp and orthoclase, limestone, pebble, gravel, sandstone, sandy, lime schist, magnesite, dolomite, marble

Low hardness rock: jaw crusher (coarse crushing first crushing), impact crusher (medium-fine crushing), and auxiliary equipment such as raw material silo, vibrating feeder, belt conveyor, circular vibrating screen. Reasonable matching according to the output demand of sandstone plant) Suitable for gravel granite, marl limestone, clay sandstone, sand mica schist, anhydrite

Advantages of the production line: The production line has reasonable configuration, stable and efficient operation, and low failure rate; high cost performance, low investment cost; good wear resistance of wearing parts, and low operating cost.

Jaw Crusher —- Coarse Crushing

Cone crusher (impact crusher) —- secondary crushing

Sand making machine —- Fine crushed sand making

Vibrating screen —- screening

Sand washing machine —- cleaning

Dewatering screen —- drying

Vibration feeder-finished product

The configuration of the specific production line needs to be estimated in conjunction with the actual situation. The processing steps may vary slightly depending on the raw materials. It is recommended that you first explain the actual requirements so that the manufacturer can customize a suitable production plan for you. LZZG equipment has reliable quality, perfect after-sales service, and reasonable process design, helping users reduce operating costs.

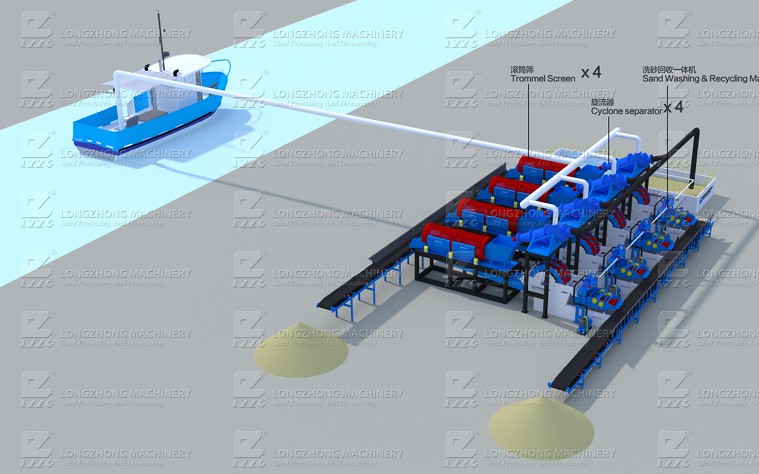

Equipment for extracting sand and gravel from river silt

Modular Construction Waste Processing Plant

Jigging machines for tungsten tin and gold ore dressing

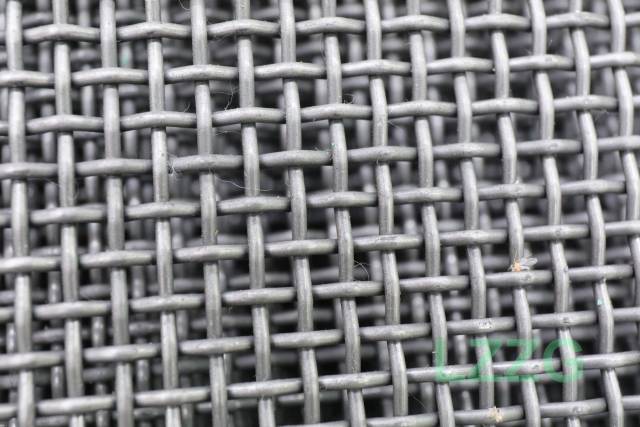

Mining wear-resistant manganese steel screen woven ore classification screen