5 Factors affecting the performance of dewatering screen

February.17,2021

February.17,2021

The performance of the dewatering screen has a great influence on the screening effect of sand and gravel. Choosing a high-performance dewatering screen can bring greater benefits to the sand washing plant. Points to know when buying a high-performance vibrating screen.

1. Vibration parameters of the sieve

It mainly refers to the working frequency, working amplitude, vibration direction angle and vibration intensity of the sieve.

For example: It is generally believed that the high vibration intensity of the sieve is beneficial to the screening effect of the sieve, but too high vibration intensity will affect the reliability index of the sieve. Comprehensive consideration, the vibration intensity of the sieve is generally 4-5g.

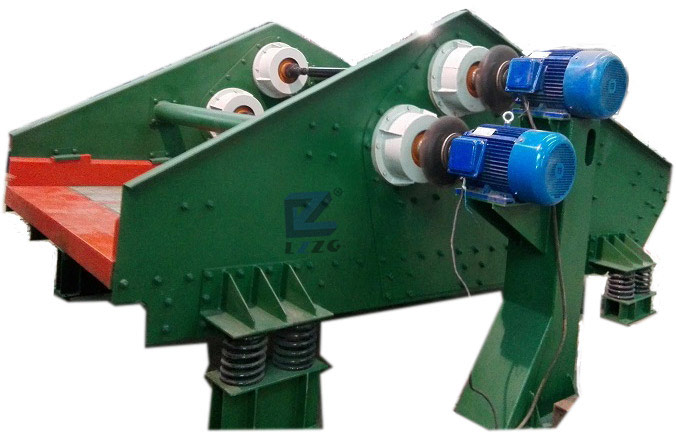

Linear (vibrating) dewatering screen

2. The structure of the sieve plate

Vibrating screens of the same specifications and models have different screening effects. The problem may lie in the structure of the sieve plate. For example, the dewatering sieve plate using polyurethane material usually has a smaller opening rate than the stainless steel sieve plate. Hole phenomenon, the screening efficiency is obviously improved.

3. The noise index of the linear (vibrating) dewatering screen is also an important index for evaluating the technical content of the screen

4. Maintenance difficulty index

The vibrating screen is as simple as possible in structure and easy to maintain.

5. Linear (vibration) dewatering screen weight index

The heavier the screen, the greater the consumption of raw materials and energy consumption, which not only increases manufacturing costs but also increases usage costs. Therefore, the sieve should be designed as light as possible.