Big capacity linear vibrating screen separating crushed ore

November.06,2024

November.06,2024

Application of LZZG large linear vibration screening machine. Many production lines also add screening processes after crushing to control the particle size of the crushed products (unqualified materials are screened out or returned to the crusher for crushing until they meet the particle size requirements). This can be called inspection screening. Its purpose is to screen out large pieces of unqualified particle size from the products of the crushing equipment so that the products do not exceed the required particle size limit.

Inspection screening is similar to independent screening, and the equipment used is mostly circular vibrating screens.

Dehydration screening-dehydration screen

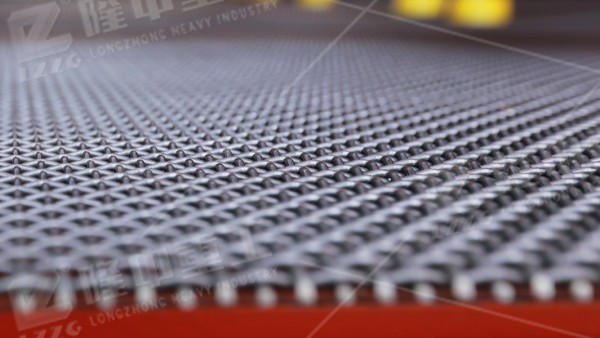

The main function of the dehydration screen is dehydration, desludging, and de-mediuming. The equipment has a low inclination angle and large linear vibration. Combined with the electromagnetic vibration net, the sand on the screen is cleaned. The sand is discharged from the screen and the water is discharged from the bottom of the screen into the tailings pump tank.

If the water content of the material in the sand and gravel production line is too high, it can be dehydrated and screened. On the one hand, it improves the product quality, facilitates storage and transportation, and reduces the transportation volume. On the other hand, it can recycle water for recycling.