Ways to control particle size in coal washing process

November.14,2023

November.14,2023

In order to effectively control coal particle size during coal washing and processing, coal companies need to determine the optimal particle size standard for the product and ensure a reasonable crushing rate. Usually, the crushing rate of the crusher is determined by the ratio of the particle size of the raw coal to the particle size of the crushed products, which is mainly the degree to which the particle size of the raw coal is reduced after processing.

In the process of raw coal processing, in order to produce coal that meets the particle size requirements, the coal preparation plant must process the raw coal deeply. The coal can be crushed by stretching, breaking, and splitting. When crushing raw coal, according to the properties of the coal itself, workers can use advanced equipment to control the energy consumption range of the crusher to improve coal crushing efficiency. Practice has shown that the traditional ruler-roller crusher consumes more energy than the classification crusher. Therefore, in the actual coal processing process, the classification crusher is most suitable for the current coal crushing work.

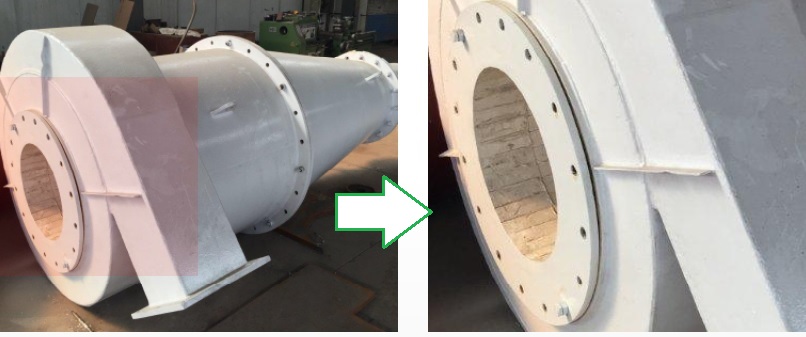

hydrocyclone in coal washing plant

In order to effectively control the particle size of coal, the coal preparation plant must formulate accurate technical requirements for particle size based on actual needs. For example, if the production particle size requirement is 50mm, then when the crushed coal particles are sent to the pressurized feed cyclone, in order to meet the strict particle size requirements, l, b, and h must be less than 50mm; if a large diameter is used For a pressureless feeding cyclone, two of l, b, and h need to be less than 50mm, and the other direction can be slightly larger than 50mm; and if you are using coal preparation equipment such as a jig that has strong adaptability to particle size , if one of l, b, h is less than 50mm.