Effect of cyclone diameter on separation particle size

March.13,2024

March.13,2024

Effect of overflow pipe diameter on cyclone separation particle size

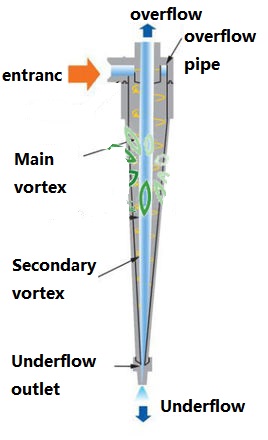

The diameter of the overflow pipe is an important parameter that affects the overall separation performance of the cyclone. Reducing the diameter of the overflow pipe within the permitted range will lead to a reduction in separation accuracy and a reduction in separation particle size. When the diameter of the overflow pipe is smaller than the flow field in the cyclone At the radius where the maximum tangential velocity is located, the separation particle size will increase instead. As for the insertion depth of the overflow pipe, its lower end surface should be higher than the cylinder-cone interface, otherwise it will aggravate the disorder of the flow field; it should not be higher than the horizontal plane of the lower edge of the feed pipe, so as not to lose its due function. As the insertion depth of the overflow pipe decreases, the separation efficiency of fine particles decreases, while the separation efficiency of coarse particles increases due to the influence of short-circuit flow.

Effect of underflow tube diameter on cyclone separation particle size

The diameter of the underflow tube has a significant impact on the separation particle size and classification efficiency of the cyclone. Generally speaking, increasing the diameter of the underflow tube is beneficial to the separation and classification of fine particles, but an excessive diameter will lead to a reduction in the concentration of the underflow, an increase in the content of fine particles, and a decrease in the classification efficiency. When it approaches and exceeds the diameter of the overflow tube, the swirl tube will The working process of the flow device will be damaged. The ratio of the diameter of the underflow pipe to the diameter of the overflow pipe (also known as the outlet ratio) should generally be in the range of 0.15 to 1.

Effect of column diameter on separation particle size of cyclone

The diameter of the cyclone column section mainly affects the production capacity of the cyclone and the particle size of solid phase separation. It is generally believed that as the diameter of the cyclone increases, its production capacity and separation particle size will increase, and the possibility of clogging will decrease, making the operation more reliable. When separating very fine solid particles, a small-diameter hydrocyclone (group) should be used. When the same separation requirements are met, a larger diameter should be used first. Since there is an effective separation process in the cyclone column section, and the longer the column section, the more complete the solid particle settling and separation process is. Therefore, for the separation of small solid particles, it is generally believed that a larger column section length can be used. The angle of the cone section is one of the main structural parameters of the cyclone and has a significant impact on the classification performance.