Fine sand making machine working principle

March.02,2021

March.02,2021

Fine sand recovery

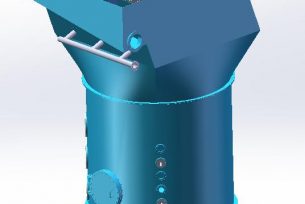

The cleaned coarse sand directly enters the screen surface, forms a filter layer on the screen surface through high-frequency vibration and is dehydrated, so as to achieve dehydration of the coarse sand; while the waste water overflowing from the sand washing machine enters the cleaning

In the tank, it is pumped to the cyclone for grading and concentration. After the cyclone separates the fine sand and water in the sand washing wastewater, the fine sand whose concentration has been increased to 60-70% is discharged into the dewatering screen.

The surface is dehydrated to realize the dehydration and recovery of fine sand.

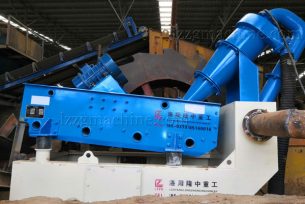

Fine sand screening

The washed sand enters the circular vibrating screen to obtain different specifications of coarse sand, medium sand, and fine sand. The circular vibrating screen uses a vibrator to generate vibration, and the circular vibrating screen is a single-shaft vibrator. The main shaft fixed on the screen box is composed of The motor drives high-speed rotation and is mounted on the eccentric body on the main shaft

Following the rotation, centrifugal inertial force is generated, so that the freely vibrating screen box produces a vibration similar to a circular track, and screens the materials on the screen.