Flotation process of gibbsite bauxite

December.27,2024

December.27,2024

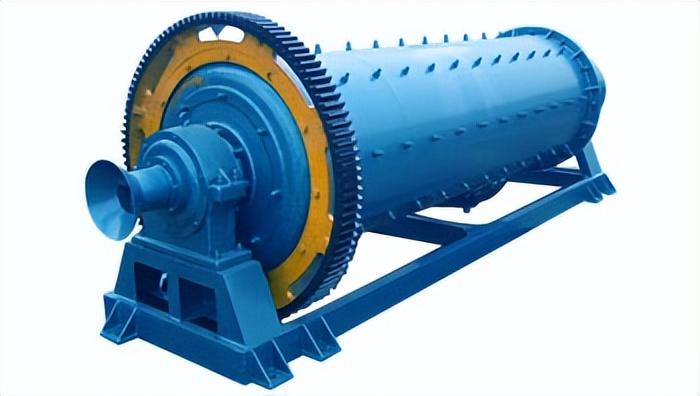

1. Gibbsite bauxite needs to be crushed and ground. Due to the high hardness of this ore, it is necessary to use equipment such as jaw crushers and ball mills for crushing and grinding. The purpose of this step is to break the ore into smaller particles and separate aluminum minerals from non-metallic minerals.

2. Washing and screening are required. This step can remove the mud and sand adhering to the surface of the ore and grade the ore. Ores of different grades will enter different flotation processes.

The purpose of flotation is to separate them by utilizing the differences in the physical and chemical properties of different mineral surfaces. In the flotation process of gibbsite bauxite, agents such as sodium oleate and oxidized paraffin are usually used to improve the flotation effect. These agents can change the wettability and electrical properties of the mineral surface, thereby achieving separation between different minerals.

3. The product after flotation needs to be dehydrated. This step is mainly to remove the flotation agent and moisture to improve the grade of aluminum concentrate. Dehydration treatment usually uses equipment such as concentrators and dryers.

4. Roasting treatment. This step can further reduce the moisture and residual flotation agent content in the bauxite and improve the grade and stability of the bauxite. Roasting treatment usually uses equipment such as rotary kilns, and its temperature and time should be adjusted according to the composition and properties of the ore.