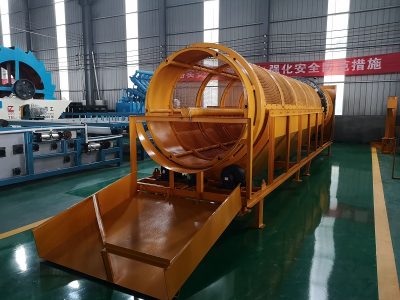

Gold Placer Water Washing Drum Screen

September.03,2024

September.03,2024

Gold placer contains more mud than primary ore, and mud easily wraps the ore sand to form cemented blocks and mud bodies. If it is directly fed into the separation process, it not only reduces the processing capacity of the ore dressing, but also seriously affects the separation process. In order to break up the mud, soaking and hydraulic flushing with water and mechanical stirring are used to separate the cemented ore sand and separate it from the clay. This is ore washing. Since the crushing operation and screening operation are carried out on the same equipment, it is customary to call the crushing and screening separation as ore washing. For example, the drum screen, flat screen and hydraulic flushing bed can complete both crushing and screening operations at the same time.

If the gold placer deposit is mined by hydraulic mining, the crushing operation is basically completed during the mining process. This is because during hydraulic mining, the cemented ore sand is impacted by the high-pressure water sprayed by the water gun and transported and lifted in the form of ore slurry. In this process, the muddy material is impacted by the hydraulic force and strongly stirred, and soaked in water for a sufficient time, so that the muddy material group is divided into fine monomer particles, and the wrapped gold particles are released.

The mud or clay in the placer gold ore has a significant impact on the washability of the ore sand. Because the clay particles are very fine, the water is firmly retained between them. Therefore, clay is actually a two-phase system composed of a solid phase and a liquid phase (water). Whether the clay-containing ore sand is easy to disperse after the crushing operation is related to the plasticity and expansion of the clay itself.