Grinding and grading with ball mill and hydrocyclone

August.07,2024

August.07,2024

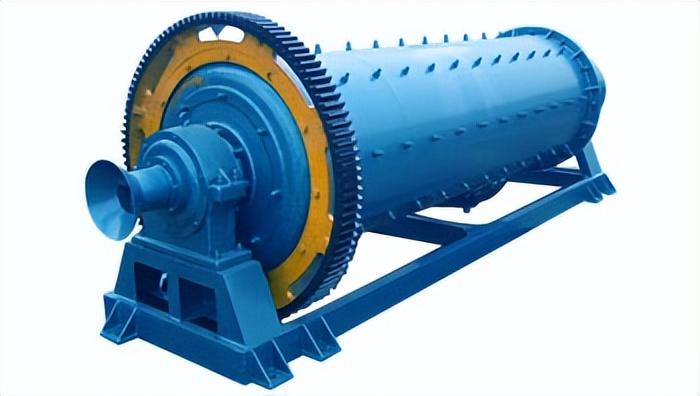

The grinding and grading stage adopts a three-stage closed-circuit grinding and flotation process. The ore particles below 15mm after being processed by the crushing equipment are sent to the ball mill for coarse grinding, and then sent to the hydrocyclone for first-stage grading. The unqualified underflow is sent back to the ball mill for grinding.

The qualified overflow is sent to the hydrocyclone for second-stage grading again. This time, the unqualified underflow is sent to the second ball mill for grinding. After qualified grinding, it is sent to the hydrocyclone for second-stage grading together with the first-stage overflow, which is the second closed circuit. In this way, the product particle size of 0-200 mesh can account for more than 80%.