How long does it take for natural stacking and dehydration of wet sand?

November.20,2023

November.20,2023

Artificial sand is generally stored and dehydrated for 3 to 5 days to reduce the water content to within 6% and become stable.

The artificial sand and gravel powder content varies depending on the initial moisture content. Generally, the stone powder content is in the range of 10% to 17%.

When the initial moisture content of wet sand is 15% to 17%, the dehydration speed is fast within about 48 hours in the initial stage. Generally, the moisture content can be reduced to 8% to 10%. When the moisture content drops to 8% to 10%, it can be reduced to 6%. The dehydration speed slows down significantly around %, generally taking 3 to 5 days. Based on the daily production of 15,000 tons of finished sand and the daily sand consumption of 1 to 15,000 tons, the finished sand warehouse has a storage capacity of 50,000 m2, and the natural dehydration time is about 5 days.

Measures to effectively control the moisture content of artificial sand in stacking sand bins

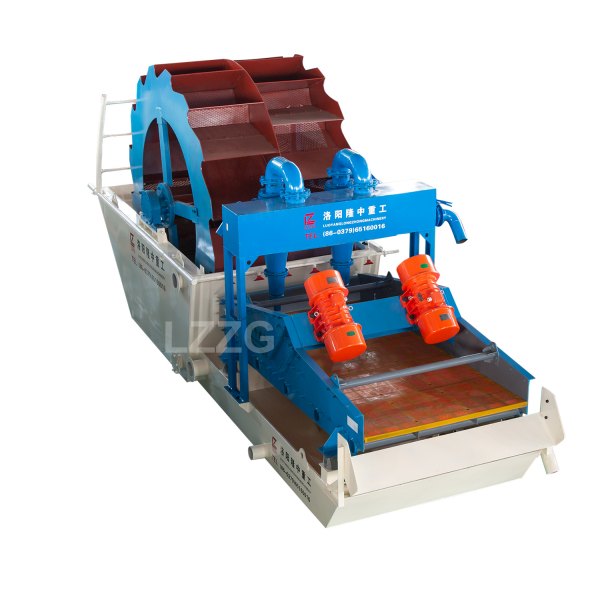

1. In the general system process, most of the water in the sand must be removed mechanically first. At present, the vibrating screen dehydration process is the most used. The sand dehydrated by the linear dewatering screen can dehydrate the sand with an original moisture content of 20% to 23% to 14% to 17%. There are also dewatering technology with good dehydration effect and correspondingly large investment costs. Vacuum dehydration and centrifugal dehydration.

2. Artificial sand unloading, storage dehydration and artificial sand extraction are carried out separately. Generally, the water content can be reduced to less than 6% and stable after 3 to 5 days of storage dehydration.

3. Mix the dry artificial sand and the artificial sand from the dewatering screen into the finished sand bin to reduce the moisture content of the sand.

4. A rainproof shed is set up on the top of the finished sand silo, and a concrete floor and blind ditch drainage facilities are poured at the bottom of the sand silo. After each bin is filled with materials, the blind ditch should be cleaned to speed up the natural dehydration time. It can also effectively reduce the moisture content of finished sand.