Limestone beneficiation process

December.24,2024

December.24,2024

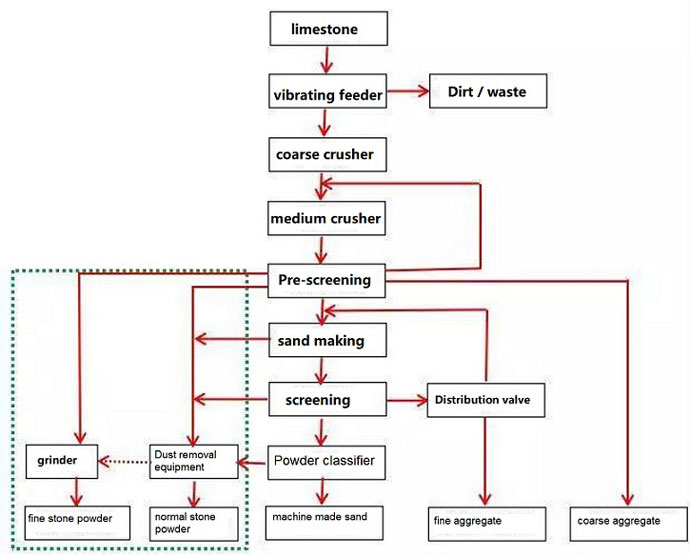

Limestone generally only needs simple ore washing, and does not need to be purified by complex ore dressing process. The processing of limestone mainly involves crushing, grading, and producing quicklime, slaked lime, precipitated calcium carbonate, ultrafine (nano) calcium carbonate, carbon dioxide, etc. Limestone generally adopts dry crushing process. For limestone used in metallurgy and roads, the ore can be crushed and screened. For the production of fine powder products, the ore is directly ground with Raymond mill after being crushed by jaw crusher, impact crusher or cone crusher. The product fineness is 100-325 mesh. The specific processing flow is as follows:

1. Coarse crushing

Limestone bulk materials are evenly fed by vibrating feeder through the silo and transported to jaw crusher for coarse crushing. The coarsely crushed materials are screened by vibrating screen and transported to impact crusher by belt conveyor.

2. Medium and fine crushing

After the coarse crushed materials transported to the impact crusher are crushed by the impact crusher, the circular vibrating screen is used to screen the crushed materials, and the larger particles are returned to the impact crusher for further crushing; if finer products or shaping are required, the crushed materials are sent to the sand making machine for further crushing and shaping.

3. Grinding

The crushed small pieces of limestone are sent to the silo by the elevator, and then sent to the grinding chamber of the mill for grinding evenly and quantitatively by the vibrating feeder.

4. Packaging

The finished materials are packaged and stored.