Mine washing waste concentration and purification system

September.26,2022

September.26,2022

The agents used in the flocculation sedimentation method mainly include two categories of coagulants and flocculants. The coagulants mainly include ferric chloride, ferric sulfate, aluminum sulfate, aluminum chloride, polyaluminum chloride (PAC), polyferric chloride (PFC), polyferric sulfate (PFS), etc. Acrylamide (PAM). The choice of coagulant is very important, it is directly related to the quality of purification effect. In recent years, the modification of traditional coagulants and the development of new coagulants have become research hotspots.

Flocculation method can effectively remove suspended particles and some heavy metal ions in beneficiation wastewater. It is a mature, stable and efficient wastewater treatment method. However, there are also problems in the incomplete purification of organic chemicals, and secondary pollution is easy to occur due to excessive dosage of chemicals. And other issues.

The wastewater that can be treated by the mine washing waste concentration and purification system includes:

(1) Mine washing wastewater: contains a large amount of fine-grained slime and a small amount of ore particles;

(2) Wastewater from crushing system: mainly contains ore particles, which can be reused after precipitation;

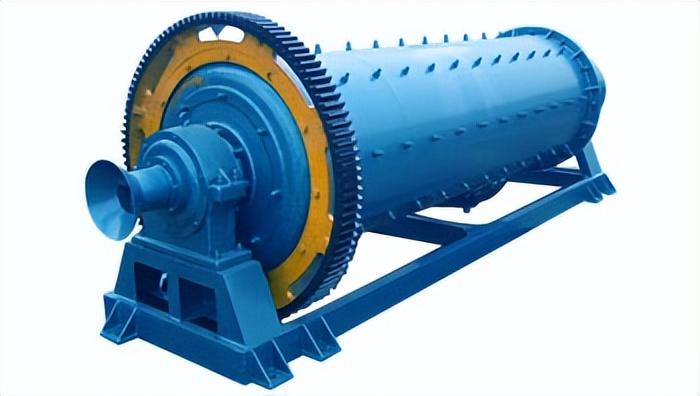

(3) Equipment cooling water: including the cooling water of the crusher, the ball mill and the water sealing water of the vacuum pump, the water volume is small, and the pollutants are mainly oily substances, which can be recycled after treatment;

(4) Gravity separation and magnetic separation wastewater: mainly contains mineral particles and suspended solids, which can be basically reused after clarification;

(5) Flotation wastewater: mainly from the overflow water and tailings pond overflow water produced after concentrate and tailings pass through the two-stage dehydration process of thickening and filtration, and contain flotation reagents and a small amount of suspended solids;