Sepiolite Processing Technology

October.14,2024

October.14,2024

The higher the purity of sepiolite, the better its physical and chemical properties and process performance, the wider its application range, and the application value will be further improved. At present, the processing of sepiolite is mainly divided into two aspects: basic processing and deep processing.

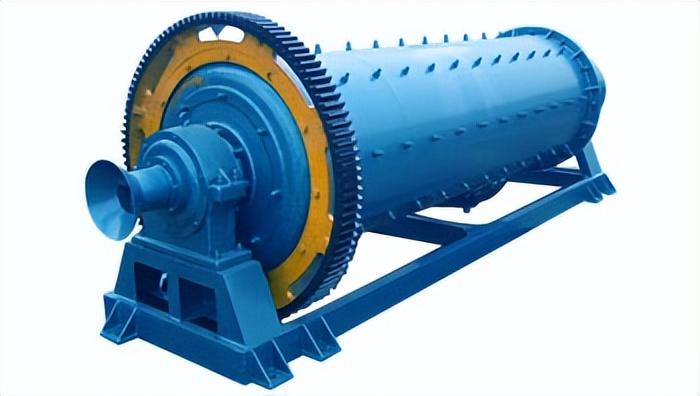

Basic processing: Ball milling and ore dressing and purification are the main methods of basic processing of sepiolite. For coarse-grained sepiolite, ball milling can obtain sepiolite with a particle size range of 0.2 to 0.6 mm. For sepiolite of different origins and different uses, different types of ball mills can be used for basic processing. Basic ball milling is not only conducive to ore dressing and purification, but also can add different components to meet the preparation requirements of various materials.

Deep processing: The application prospects of sepiolite depend on the degree of deep processing. The deep processing of sepiolite mainly includes ultrafine processing, activation, surface modification treatment and other methods. Among them, ultrafine processing usually uses air flow mills and high-speed mechanical impact mills for processing according to different requirements for product fineness. At present, the main methods for modifying sepiolite include acid modification, ion exchange modification, roasting treatment modification and organic modification.