What is the use of stone powder produced in the production of artificial sand?

July.04,2024

July.04,2024

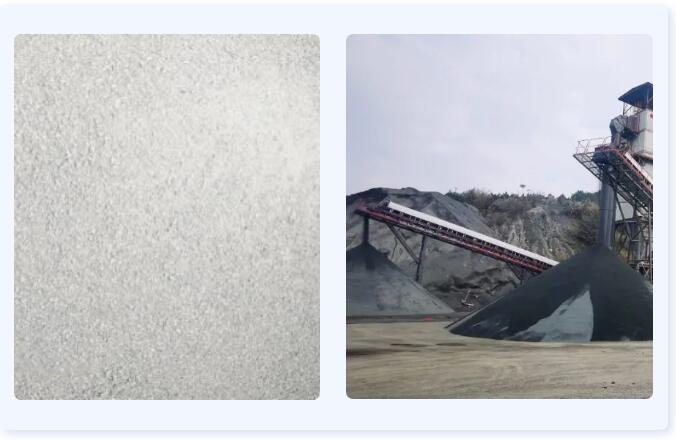

In recent years, the use of artificial sand to replace natural sand has become an inevitable trend in the sustainable development of concrete. However, due to the limitations of artificial sand-related standards and current production processes, artificial sand production will produce a large amount of excess stone powder, which is usually discarded by stacking or landfilling.

Using the excess waste stone powder in artificial sand as a mineral admixture can not only achieve its high added value utilization, but also help solve the shortage of traditional mineral admixtures.

The feasibility study of waste stone powder as a concrete mineral admixture shows that:

(1) Waste stone powder has a smaller specific surface area and a larger MB value than ground stone powder, which is attributed to the fact that waste stone powder is a byproduct of artificial sand and contains more clay minerals than ground stone powder. Both waste stone powder and ground stone powder will reduce the fluidity of the mixture, but the reduction is small.

(2) Waste stone powder will reduce the compressive strength of concrete at all ages, and the degree of reduction in the strength of high-strength concrete is smaller than that of low-strength concrete. This is because waste stone powder increases the porosity of low-strength concrete but has little effect on its pore structure characteristics.

(3) Waste stone powder as a mineral admixture can effectively reduce the carbon emissions of concrete throughout its life cycle. The percentage of carbon reduction in the total carbon emissions is basically equal to its admixture dosage. In addition, the carbon reduction benefit is more significant when waste stone powder is used in high-strength grade concrete.