Strategies to reduce the cost of sand and gravel plants

December.29,2022

December.29,2022

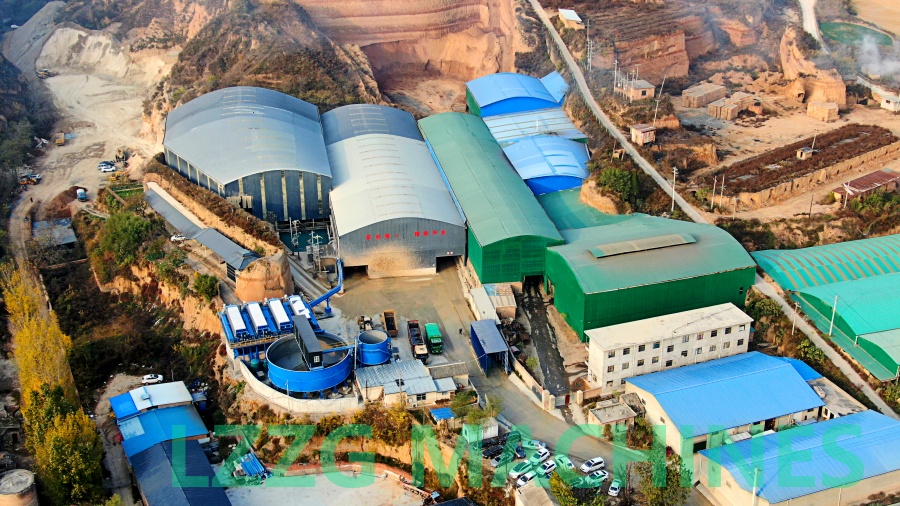

Reasonable scale and site layout

Before purchasing a complete set of equipment for a sand and gravel aggregate production line, it is necessary to determine the scale and choose a crusher. In particular, it is necessary to choose a good supplier of stone production line equipment, and choose a reputable and responsible manufacturer. Unreasonable equipment configuration and unreasonable layout plan will directly affect the future production cost.

Timely maintenance

After the stone material production line enterprise is established, it must have a reasonable manpower allocation: because the working environment of the crushing machinery is harsh, it is more prone to problems, there must be one mechanic in each shift, and this person must often inspect the crushing machinery and belt conveyors, adhere to the shift system, Refueling, tightening bolts, tensioning belts, etc., spare parts must be fully replenished in time, so as to better save production costs.

Improve the utilization rate of production materials

The production material has the greatest impact on the cost of the entire production process. Therefore, only by increasing the utilization rate of production materials to the greatest extent can the production cost be well controlled, and the waste of sand and gravel aggregates can be minimized. It is especially important for the link of sorting and finished product stacking and transportation.