The difference between polyurethane screen and steel screen

December.12,2024

December.12,2024

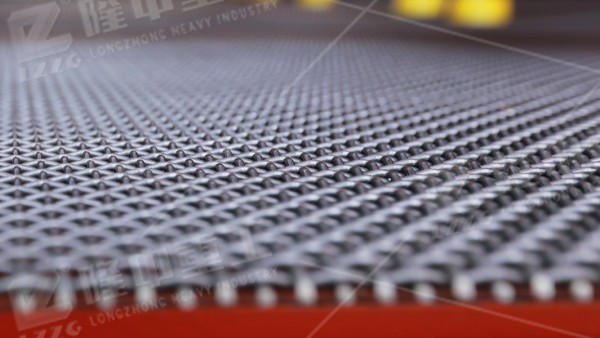

Polyurethane has low strength and relatively high toughness. In order to resist the damage to the screen caused by aggregate falling from the belt conveyor, there are certain requirements for the width and thickness of the screen reinforcement. It cannot be too thin or too thin. When the screen size of the vibrating screen is certain, it is inevitable to reduce the opening rate of the screen, which will reduce the screening rate of the screen. Among the four screens, the polyurethane screen has the lowest screening rate.

The steel screen has high strength and strong resistance to aggregate impact. The surface of the steel bar is smooth and flat, which can well reduce the obstruction of the aggregate in motion. It can also have a good opening rate while ensuring the strength of the screen, thereby greatly improving the screening rate of the screen.

The main material cost of the polyurethane rubber screen is high, but the advantage is that there is no necessary production cost and the labor cost is also low. No other auxiliary tools (crane) are required during installation, and the installation can be completed by manual labor alone.

The main material cost of steel bar screen and square steel screen is relatively low, but the production cost is relatively high. It takes a lot of manpower and time to produce, which is time-consuming and labor-intensive. Auxiliary tools are required during the installation process, which will also incur certain costs.