The difference between shaftless drum screen and shaft drum screen

April.18,2023

April.18,2023

Shaft drum screen: used for grading large and small stones and separating soil and stone powder in the quarry; used for sand separation in the quarry; used for separation of lump coal and coal powder and coal washing in the coal industry; used in the chemical industry and mineral processing industry Classification of large and small lumps and separation of powdery substances.

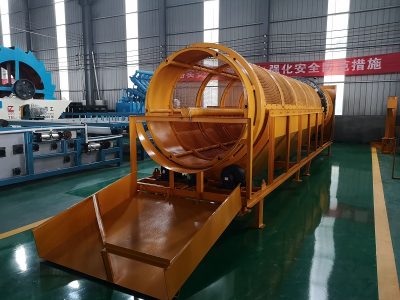

Shaftless trommel screen: It is mainly used for grading treatment of strip-shaped and highly entangled materials, and is widely used in electric power, mining, metallurgy, building materials, chemical and other production industries. It is often used in the classification of refractory materials, coal, chemical fertilizers, and stones in sand pits, as well as the screening of sticky and wet materials such as coal, coke, lime, placer gold, etc., to make the product structure more uniform and meet production needs.

Compared with the trommel screen with a central shaft, the structure of the shaftless trommel screen is simpler. At the end of the trommel screen close to the motor, several steel bars are evenly welded around the drum, and the other end of the steel bars converges. To the central axis of the drum, after being fixed, it is connected to the motor through gears. When the motor is started, the drum will rotate accordingly, which is the same screening principle as a drum screen with a shaft. Shaftless trommel screens are relatively more material-saving, have a larger space for screening materials, and are easier to repair when the drum fails, so shaftless trommel screens are used a lot. The advantage of the shaftless drum screen is that it can avoid the winding of materials, and the screening efficiency is relatively high. The throughput of the shaftless trommel is 20% higher than that of the shafted trommel.