Wear-resistant ceramic liner hydrocyclone for coal washing

September.22,2020

September.22,2020

The hydrocyclone can effectively classify and concentrate the slime water and has a simple structure and easy maintenance. It is widely used in coal preparation plants.

Wear-resistant ceramic liner is a wear-resistant material for material transportation equipment in petroleum, mining, steel mills, power plants and other industries or liquids flowing through the surface of the pipeline. The main function is to effectively resist the impact of materials on the pipe wall when the material passes through, and the corrosion of chemical substances The function and the thermal shock effect of the material after the process, reduce the wear of equipment components, thereby greatly reducing the cost of frequent maintenance, extending the service life of the equipment, the best choice for sand washing plants and mud purification systems.

Characteristics of wear-resistant ceramic liner

The cyclone has the characteristics of abrasion resistance, impact resistance, corrosion resistance, high-temperature resistance, and convenient construction. It is an ideal wear-resistant material for conveying ash, coal powder, mineral powder, tailings, and cement. It is very safe and reliable to use in abrasion or high temperature erosion occasions. Its life span is ten to twenty times longer than that of cast stone, wear-resistant alloy cast steel, steel plastic, steel rubber and other materials.

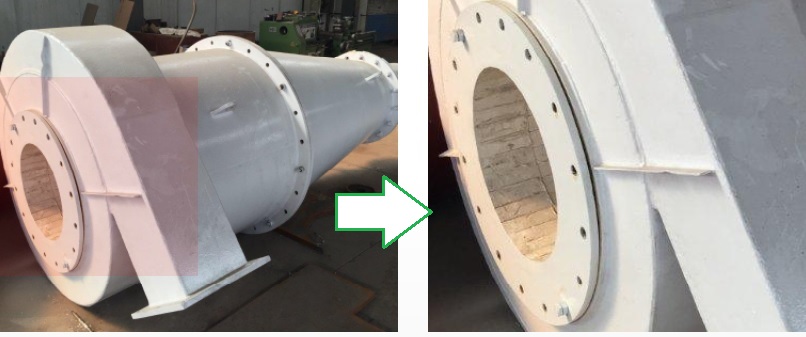

Wear-resistant ceramic liner installation

There are two types of welding and gluing. It depends on the specific construction environment. Welding is generally used under conditions of greater impact. The adhesive is affected by the adhesive, and the temperature cannot exceed 300 degrees.