What equipment is good for granite sand making?

July.19,2024

July.19,2024

Granite is a kind of rock with high hardness, which is difficult to process and has high requirements for crushing equipment. For the crushing of granite, the following equipment can be selected:

Jaw crusher. It is mainly used for the first crushing process of the crushing production line. It can crush large-particle materials with a compressive strength of less than 320 MPa, and the crushed finished product is about 100 mm to 300 mm.

Cone crusher. It uses the principle of layered crushing to form a material layer protection layer. It has the characteristics of high crushing efficiency, convenient adjustment, reliable structure and economic use.

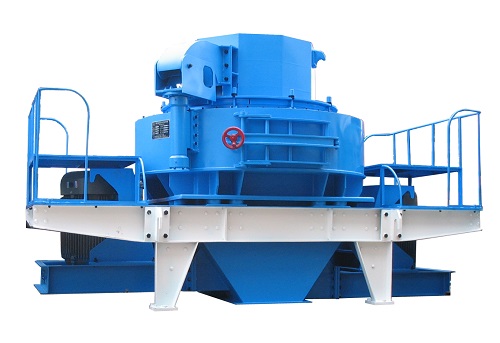

Sand making machine. It is suitable for crushing and sand making of soft, medium-hard and hard materials. It is generally used as the last process of the crushing and sand making production line. The feed particle size is 30 to 60 mm. It can turn granite into sand and is deeply loved by users.

Mobile sand making machine. It has extremely strong mobility, compact overall structure design, modular installation, eliminates the restrictions of crushing site and environment on crushing equipment, can greatly reduce the cost of material transportation back and forth, and has oil-electric dual configuration, which is both environmentally friendly and high-yield.

Hydraulic roller sand making machine. It is suitable for crushing hard rocks such as granite. It has the characteristics of high efficiency, energy saving, environmental protection, etc., and can be easily and quickly maintained.

In addition, for the crushing of hard rocks such as granite, multi-stage crushing modes can be adopted according to different production conditions. The two-stage crushing mode includes jaw crusher + cone crusher, the jaw crusher is responsible for coarse crushing, and the cone crusher is responsible for medium and fine crushing. The three-stage crushing mode adds a vertical shaft impact crusher on the basis of two-stage crushing, which is used for stone shaping and machine-made sand production. The four-stage crushing mode is mainly for medium and fine crushing. At the same time, single-cylinder hydraulic cone crusher and multi-cylinder hydraulic cone crusher are selected, which is suitable for medium and large hard rock crushing projects.