How to reduce vibrating screen noise and dust

August.01,2019

August.01,2019

The vibrating screen is a kind of equipment used for screening materials, and has the characteristics of large output, simple structure and long service life. When it is running, the vibration motor will generate a large amount of mechanical noise. At the same time, due to the collision of materials in the screening and transportation process, a large amount of dust is generated. How can we solve the problem of noise, dust and other environmental impacts? What about the problem?

Vibrating screen noise slove method

1, with higher precision bearings

The vibration generated by the bearing during operation includes two aspects:

Structural aspect: the rolling element causes a small change in the position of the shaft center to cause vibration by the action of recombination;

Manufacturing aspect: the geometrical errors of the rolling elements, inner and outer rings, cages, etc. after rolling will cause vibration.Load, speed, lubrication and working clearance will affect the vibration of the bearing to varying degrees. Therefore, when selecting the bearing, the bearing life condition should be satisfied first. Secondly, the bearing with smaller size and higher precision should be used as much as possible. .

2, polyurethane sieve plate instead of metal sieve plate

Because the polyurethane material has a small elastic modulus and a large internal resistance, the use of a polyurethane sieve plate can effectively reduce noise. According to a French data, the noise of the polyurethane sieve plate can be 15~20dB (A) lower than that of the ordinary metal sieve plate under the same excitation condition. However, since the noise of other components such as the side panels has not yet fallen, the overall noise of the vibrating screen can be reduced by 5 dB (A) in actual use.

The vibration screen of lzzg not only has polyurethane sieve plates of various sizes, but also the rubber dehydration screen base is equipped with a rubber spring, and the spring end and the support have relative sliding. Since it is dry friction, the friction noise frequency is high and the sound is large. The use of rubber springs greatly reduces the frictional noise of the parts produced by vibration.

3. Screen box side plate plus constrained damping layer

The plate structure of the side plate and the rear end plate of the screen box are all-welded or riveted by the thin plates. These large-area thin plates radiate strong noise under the action of the exciting force, and the radiation noise level and the surface of the plate surface The square of the vibration speed is proportional to this. For this purpose, a restraining damping material can be applied to the surface to achieve the purpose of noise reduction.

4, chute plus rubber liner

The vibrating screen has a feed chute and a discharge chute. The chute is welded by a steel plate. The collision and friction of the material in the chute also affect the noise of the vibrating screen. For this purpose, rubber is laid on the inner wall of the feeding and discharging chute. The lining also reduces chute noise.

Treatment method for vibrating screen dust

1. Vibrating screen feed port dust

Due to the large amount of materials piled up, the vibrating screen feed port is prone to generate more dust. Especially for some large-volume vibrating screen equipment with a production capacity of about 1,000 tons, the amount of dust is much more, and it can be closed at the top of the equipment. The silo and the feed port are sealed to reduce the probability of the raw materials being exposed to the outside. The belt conveyor belt is transported inside the silo, which can also speed up the material transfer.

2. Dust during vibration

Due to the strong vibration during the operation of the vibrating screen, a large amount of dust is also generated. On the one hand, the outside of the device is sealed, and on the other hand, the dust removing device disposed on the device is also very necessary. The position of the vibrating screen dust distribution is relatively dense, not only distributed in the screen surface, but also in the gap between the screen surface and the feed port, there will also be dust overflow, so all the protective measures can be made to make the vibrating screen realize the dust-free screen. Minute.

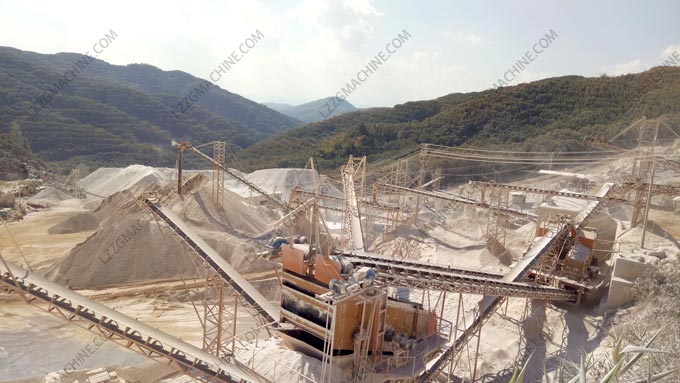

LZZG has senior design engineers of the mining machinery and industrial milling equipment, domestic and foreign famous universities, degrees, and other technical elites, to provide an inexhaustible driving force for sustainable development of enterprises, and they work together to ensure the long product development, design, production and after-sales service in every aspect of efficient and perfect. Vibrating screens were exported to Indonesia, Thailand, Vietnam, Australia, Europe, South Africa, etc.