Basalt Sand Production Plant Fineness Control And Imporve Capacity

April.05,2023

April.05,2023

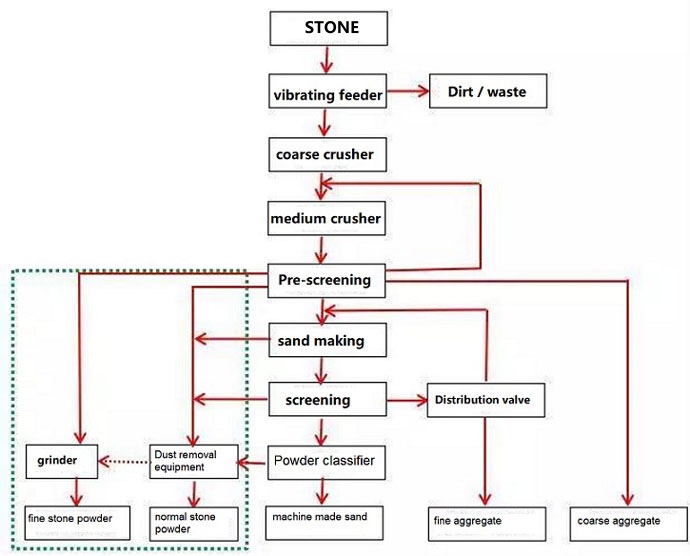

In view of the low sand-making rate of basalt sand, high fineness modulus of finished sand and low stone powder content, the following corresponding measures are mainly adopted:

First, increase the rotor speed of the vertical shaft impact sand making machine, increase the linear velocity of the aggregate in the crushing cavity (the system takes 65m/s), increase the sand forming rate, and the stone powder content of the crushed sand, while reducing the fineness of the sand degree modulus;

Second, adjusting the feed gradation of the vertical shaft impact crusher can greatly improve the sand making effect;

Thirdly, after coarse crushing and medium fine crushing, the <5mm aggregates produced by the system have a high content of stone chips. The process allows this part of aggregates to produce finished materials, and the medium and fine crushed aggregates <5mm all enter the vertical shaft impact crusher for shaping. To control the quality of finished sand;

Fourth, the vertical shaft impact crusher processes the aggregates graded by the second screening workshop, among which some coarse particles (mainly 3-5mm) of <5mm will not leave the finished material, and let them enter the rod mill for re-crushing to adjust The fineness modulus and stone powder content of the finished material;

Fifth, when the vertical shaft impact crusher is used for sand making, the lower the moisture content of the processed aggregate, the better the sand making effect. According to this feature, the system adopts the full dry method of production to improve the sand making effect of the sand making machine.